The global demand for rare-earth elements (REEs) has surged dramatically in recent years, primarily due to their critical role in modern technologies, especially those aimed at promoting sustainability. As nations strive for a carbon-neutral future, there is an increasing reliance on renewable energy sources, electric vehicles (EVs), and high-performance magnets, all of which utilize REEs like neodymium (Nd) and dysprosium (Dy). Unfortunately, the conventional methods of obtaining these materials often lead to significant environmental damage and resource depletion. However, recent innovations in recycling technologies could change the game, offering a pathway to sustainable resource management.

A group of researchers at Kyoto University, led by Professor Toshiyuki Nohira, has made a noteworthy advancement in the field of REE recycling through their development of the selective extraction–evaporation–electrolysis (SEEE) process. This sophisticated method is designed to enhance recycling efficiency while substantially minimizing the environmental footprint associated with traditional techniques. The SEEE process not only separates REEs effectively but also does so in a way that aligns with the sustainability goals of the global community.

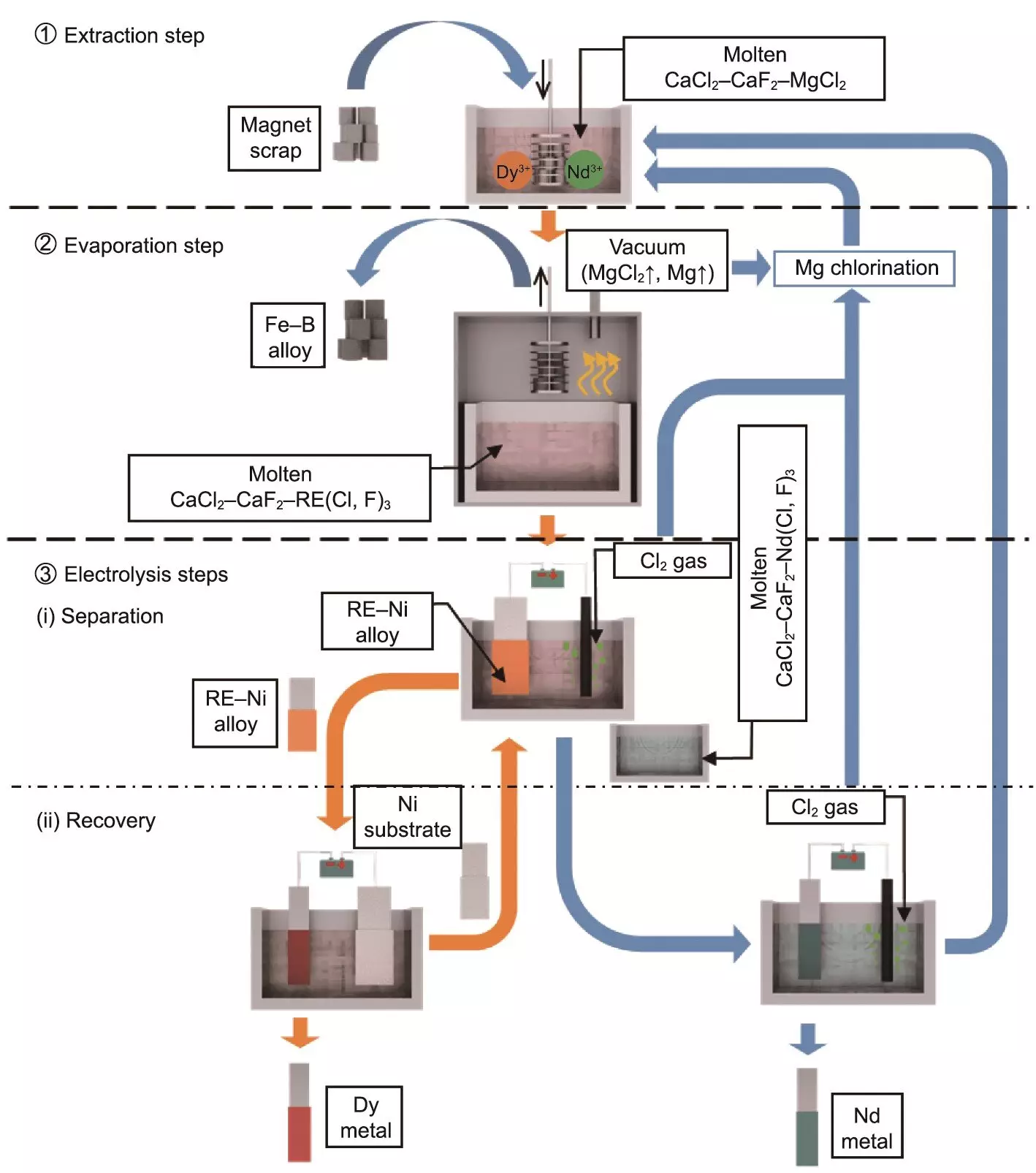

The SEEE process is segmented into three distinct phases—each contributing to a more refined and effective strategy for recovering valuable REEs.

1. **Selective Extraction**: In this initial stage, a unique molten salt mixture, including calcium chloride (CaCl2) and magnesium chloride (MgCl2), is employed to extract REEs from discarded magnets. The inclusion of calcium fluoride (CaF2) plays a crucial role in enhancing extraction efficiency by controlling evaporation losses.

2. **Selective Evaporation**: This phase is focused on eliminating residual extraction agents and byproducts post-extraction. By concentrating the REEs during this step, the process ensures that the highest quality outputs are obtained for the subsequent stages.

3. **Selective Electrolysis**: The final phase employs electrochemical methods to separate the extracted REEs based on their distinct formation potentials. This technique allows for the recovery of high-purity metals, significantly enhancing the quality of the recycled materials.

The preliminary findings from the SEEE process are impressive, boasting recovery rates of 96% for neodymium and 91% for dysprosium, with purities surpassing 90%. Such achievements underline the considerable advantages this innovative method presents over existing recycling techniques, which are often characterized by prolonged procedures and substantial ecological consequences.

As the global landscape shifts toward a greater adoption of electric vehicles and renewable energy solutions, the significance of the SEEE process becomes even more pronounced. The ability to recycle these critical elements effectively means a decreased dependency on mining operations—activities that typically lead to severe environmental degradation. Notably, this process doesn’t just stop with Nd and Dy; its versatility means it could also be adapted for different sectors, such as nuclear fuel reprocessing, positioning it as a potential cornerstone of sustainable materials innovation.

The Future of Recycling and Sustainability

While the SEEE process has shown remarkable potential, it is important to ground expectations in realism. Researchers acknowledge that technical refinements and further investigations are needed to fully implement this process in industrial settings. Nonetheless, the groundwork laid by this research highlights the necessity of advanced technology in addressing the multifaceted challenges surrounding REE recycling and environmental sustainability.

The commitment to developing innovative solutions like the SEEE process is exemplary of the proactive approaches needed to support broader global efforts aimed at achieving carbon neutrality. As technology continues to advance, the significance of effective and efficient recycling solutions cannot be overstated. This movement toward sustainable resource management marks a crucial step in safeguarding our planet while navigating the complex dynamics of modern technology’s demands.

The groundbreaking work by Kyoto University researchers emphasizes the integral role of innovation in addressing environmental challenges. By rethinking how we recycle rare-earth elements, the SEEE process not only presents a practical solution but also echoes the urgent necessity for sustainable practices in the face of escalating demand for resources. The path forward requires a concerted effort in research, development, and, eventually, implementation on a large scale. Only by prioritizing such innovations can we hope to foster a sustainable future free from the pitfalls of resource depletion and environmental harm.