Industrial processes are integral to modern economies, yet they often come at a significant environmental cost. Among the numerous pollutants generated, nitrogen oxides (NOx)—a collective term encompassing nitric oxide (NO) and nitrous oxide (N2O)—stand out due to their detrimental effects on both human health and the environment. Nitric oxide is notorious for contributing to respiratory issues and acid rain, while nitrous oxide, recognized as laughing gas, is a potent greenhouse gas that exacerbates climate change. In light of this, effective emission control technologies are essential, and zeolite-based catalysts have emerged as a promising solution in the fight against these toxic gases.

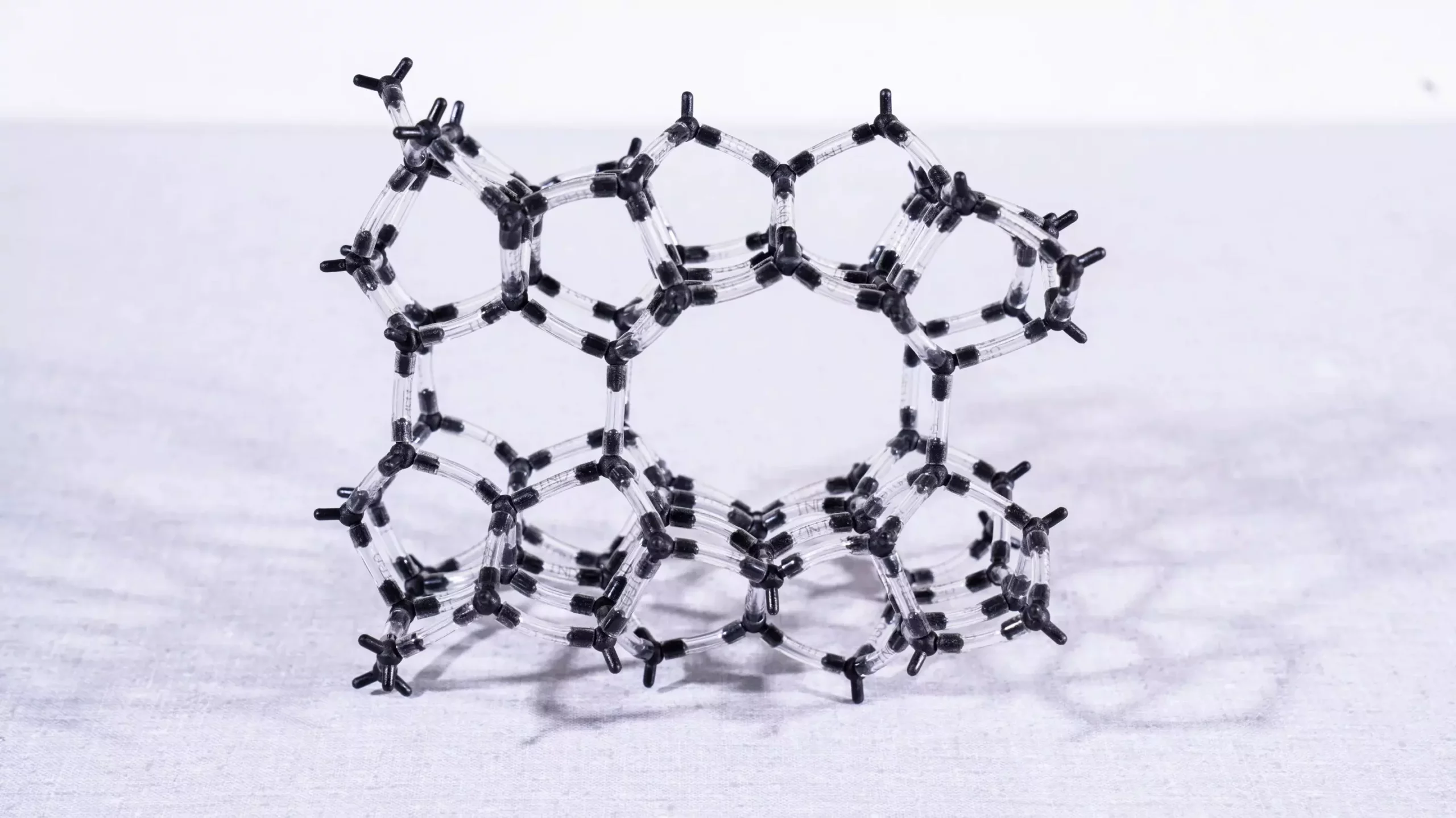

Zeolites, crystalline aluminosilicates with a unique porous structure, have been widely utilized in various chemical applications due to their catalytic properties. These materials can be naturally occurring or synthesized for specific industrial uses, often incorporating additional elements to enhance their functionality. Recent research from the Paul Scherrer Institute (PSI) in Switzerland, conducted in collaboration with CASALE SA, sheds light on the intricate workings of zeolite catalysts in converting nitrogen oxides into benign substances.

The study reveals that individual iron atoms embedded within the zeolite framework play a pivotal role in driving the catalytic reactions. Iron can exist in various configurations, ranging from solitary atoms to clusters of multiple atoms, each influencing the catalyst’s efficiency differently. Understanding which specific iron species are active during the catalytic process is crucial for optimizing these materials for environmental protection.

To unravel the complex interactions within zeolite catalysts, the research team employed a multifaceted approach involving several advanced spectroscopic techniques. Utilizing the Swiss Light Source (SLS) for X-ray absorption spectroscopy allowed researchers to gain a comprehensive view of the iron species present in the zeolite while the catalysis reaction was occurring. Complementing this, electron paramagnetic resonance spectroscopy, executed in collaboration with ETH Zurich, facilitated the identification of the contributions of each iron species involved in the process. Finally, infrared spectroscopy was employed to analyze the molecular interactions associated with the various iron configurations.

Through this triad of analytical techniques, the researchers were able to pinpoint the exact conditions under which the catalytic activity occurred, specifically focusing on two neighboring iron atoms within the zeolite structure. This remarkable arrangement enabled a collaborative reaction pathway where one iron atom facilitated the conversion of nitrous oxide while the other processed nitric oxide, thereby working in unison to achieve the simultaneous abatement of both gases effectively.

One of the most significant revelations from this research is the potential to tailor the manufacturing processes of zeolite catalysts based on a deeper understanding of their catalytic mechanisms. By knowing precisely where and how the catalytic reactions occur, engineers and chemists can design more efficient and targeted catalysts that not only reduce nitrogen oxide emissions but do so with greater efficacy. The implications extend beyond merely fulfilling regulatory requirements, as improved catalysts can lead to cost-saving efficiencies for industries reliant on combustion processes, such as power generation and transportation.

The removal of nitrogen oxides from industrial emissions is not simply a technical challenge; it reflects a broader responsibility that industries have toward environmental stewardship and public health. The findings reported in Nature Catalysis underscore the intricate balance of chemical interactions necessary for the effective operation of zeolite-based catalysts. By continuing to research and refine these materials, industries can significantly mitigate the harmful effects of their emissions.

The exploration of zeolite catalysts represents a promising frontier in emission control technology. With the potential to drastically reduce toxic nitrogen oxides from industrial processes, ongoing research in this area is essential for securing a cleaner and healthier environment for future generations. The work of institutions like PSI and their industrial collaborations is vital in developing innovative solutions to some of today’s most pressing environmental challenges.