As the world shifts toward sustainable energy solutions, sodium-ion batteries (SIBs) are emerging as a promising alternative to the ubiquitous lithium-ion batteries (LIBs). Harnessing sodium—an element abundant in nature compared to lithium—these next-generation batteries offer several advantages, including lower costs and enhanced safety due to their reduced reactivity. However, despite their promise, SIBs have faced challenges primarily associated with lengthy and complex manufacturing processes, particularly in the production of hard carbon anodes.

Hard carbon is essential for sodium-ion batteries because of the larger size of sodium ions in comparison to lithium. This necessity arises from the requirement for increased interlayer spacing, which is a hallmark of hard carbon as opposed to traditional graphite used in lithium-ion batteries. Notably, hard carbon is not naturally occurring and must be synthesized—a process that has proved economically and environmentally burdensome due to high temperature and energy demands. Currently, the carbonization of hydrocarbon materials at temperatures exceeding 1,000°C for prolonged periods constitutes a significant barrier to the widespread adoption of sodium-ion technologies.

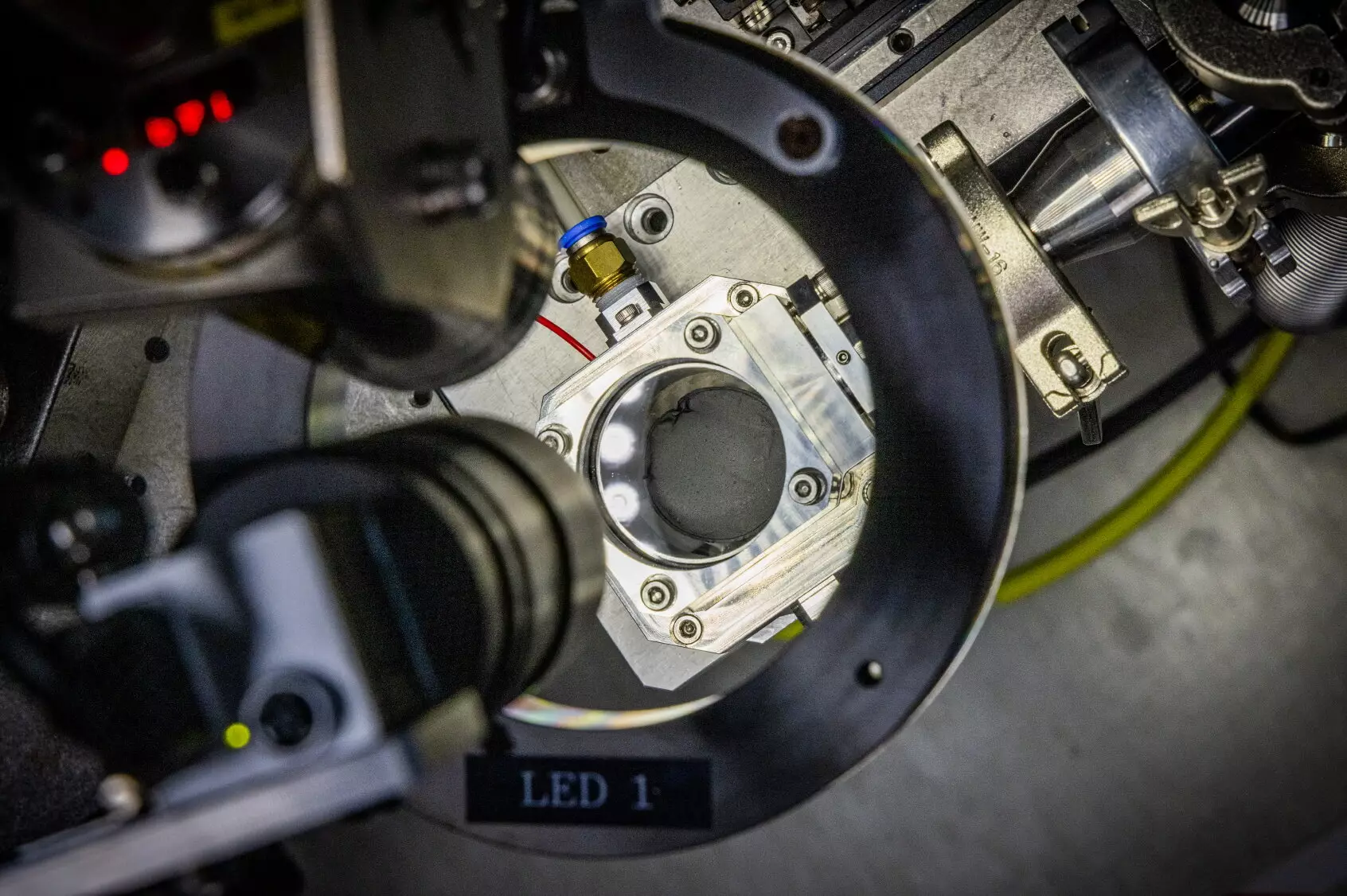

Amidst these challenges, a research team led by Dr. Daeho Kim and Dr. Jong Hwan Park has pioneered groundbreaking advancements using microwave induction heating technology. This revolutionary method, reminiscent of the household microwaves used for cooking, drastically reduces the preparation time for hard carbon anodes to just 30 seconds. By combining polymer films with highly conductive carbon nanotubes and subjecting them to microwave magnetic fields, the team achieved impressive temperatures—over 1,400°C—required for carbonization in a fraction of the time previously needed.

This innovation not only addresses the time constraints of the carbonization process but also opens doors to improved energy efficiency and cost-effectiveness, key factors vital for the commercialization of sodium-ion batteries. The success stems from their meticulous approach to utilizing multiphysics simulation techniques, which provided deep insights into the electromagnetic interactions at play in microwave treatments of nanomaterials.

Published in the Chemical Engineering Journal, the study’s findings have captured significant attention within both academic and industrial circles, fueling interest in the energy storage sector. The pivotal contributions of student researchers Geongbeom Ryoo and Jiwon Shin showcase the effectiveness of KERI’s collaborative research programs, highlighting the potential of academic partnerships in developing cutting-edge technologies.

Dr. Park emphasized the urgency of pursuing safer battery technologies, particularly in light of recent concerns surrounding fires in electric vehicles. The innovative microwave technology not only promises enhanced performance across varied conditions, including low temperatures, but also addresses some of the critical safety concerns associated with traditional lithium-ion batteries.

The implications of this research extend far beyond just sodium-ion batteries. As the KERI team looks to advance their technology, they also aim to scale up production capabilities, creating the possibility of mass production of large-area hard carbon films. Such advancements could result in reduced costs and increased accessibility of sodium-ion batteries for widespread use.

Moreover, they foresee potential applications of microwave induction heating technology in other domains, including all-solid-state batteries that require high-temperature sintering. This exploration of cross-disciplinary applications exemplifies the innovative approach of KERI researchers, demonstrating a proactive stance in adapting their technologies to meet the growing demands of energy storage solutions.

KERI’s strategic foresight in filing domestic patent applications suggests a robust interest in attracting industry partners for technology transfer. As companies within the energy storage sector increasingly look toward sustainable and efficient solutions, the potential for collaboration and commercialization of this technology appears promising.

The groundbreaking work by Dr. Kim, Dr. Park, and their team not only revolutionizes the preparation of hard carbon anodes but also positions sodium-ion batteries as a viable alternative to lithium-ion technologies. With ongoing research and development efforts, the future of battery technology looks brighter than ever.