Plastic pollution has become a pressing global dilemma, as the accumulation of plastic waste in our environment poses significant threats to ecosystems and human health. Despite the increasing awareness of this issue, the rates of plastic recycling, particularly through chemical means, remain disappointingly low. Traditional recycling processes are often inefficient and resource-intensive, hindering their effectiveness in addressing the plastic crisis. The need for innovative and sustainable solutions in waste management has never been more urgent.

In an impressive stride towards mitigating plastic waste, a research group led by Professor Kotohiro Nomura at Tokyo Metropolitan University has unveiled a novel technique for the depolymerization of polyethylene terephthalate (PET). By employing alcohols and an accessible iron trichloride catalyst, the team has successfully developed a method for selective chemical recycling of PET materials sourced from both textiles and plastics. The findings, which are published in the esteemed journal Industrial Chemistry & Materials, offer a transformative approach to reducing plastic waste while recovering valuable raw materials.

Polymers such as polyesters are characterized by their ester bonds, which form through the reaction of carboxylic acids and alcohols. Within the realm of plastics, polyester is prevalent in everyday items like plastic bottles and clothing. The challenge lies in effectively breaking these ester bonds to revert polyester back to its raw components. Conventional depolymerization techniques typically require high temperatures and the use of large quantities of strong acidic or basic substances, raising concerns over their environmental impact. Therefore, the pursuit of an efficient, cost-effective, and eco-friendly method of depolymerization is critical in advancing plastic recycling technologies.

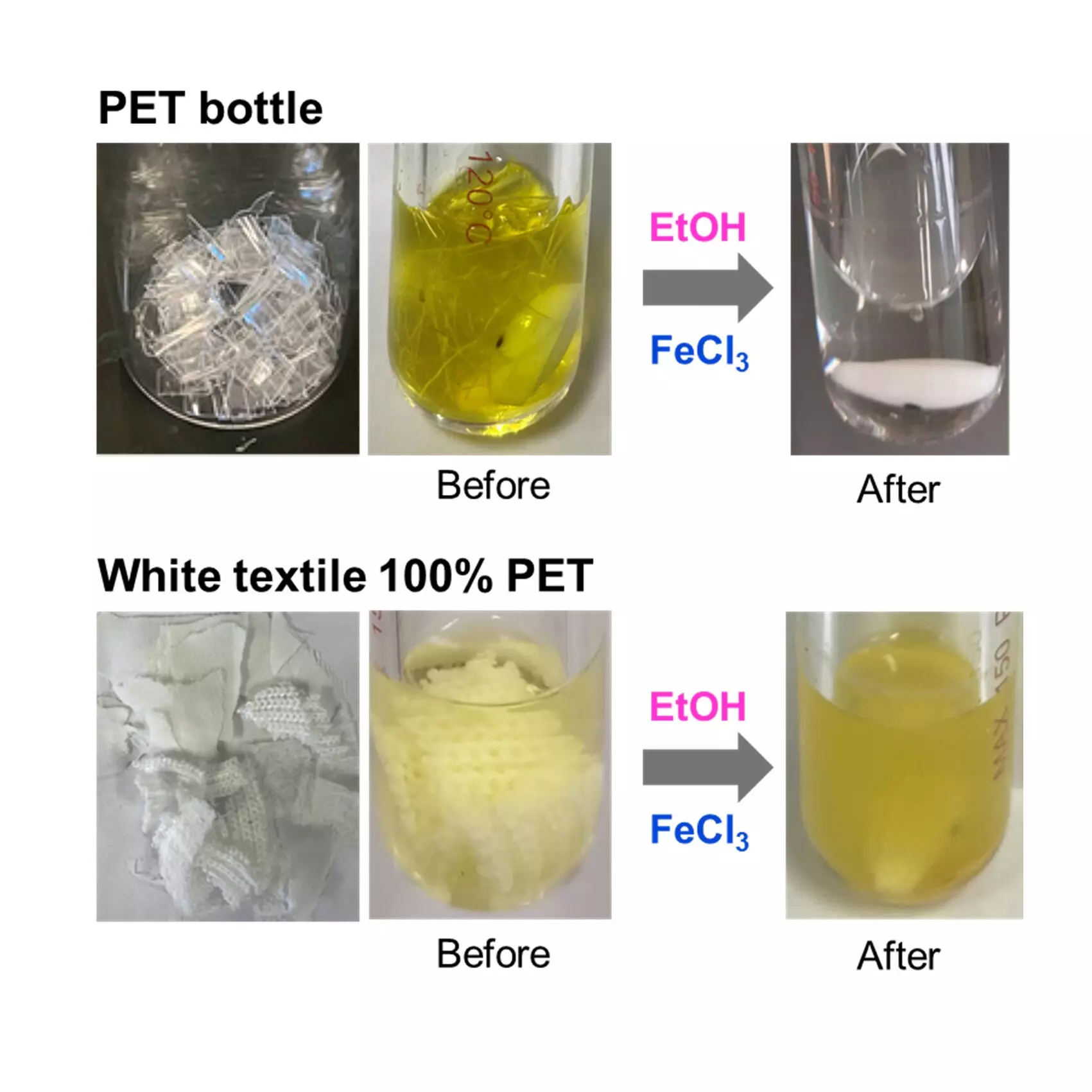

The breakthrough methodology developed by Nomura’s team utilizes ethanol in conjunction with inexpensive catalysts like iron trichloride (FeCl3) or iron bromide (FeBr3). Experiments revealed that this approach yields diethyl terephthalate (DET) and ethylene glycol (EG) with exceptional purity, boasting selectivity rates above 98%. The process operates at moderate temperatures between 160°C and 180°C, showcasing the strong performance of FeCl3—addressing concerns about both operational costs and environmental sustainability.

Significance for Textile Waste Recycling

One of the remarkable applications of this method is its ability to selectively extract PET from textile waste, which often consists of a blend of polyester and cotton fibers. This advancement not only recovers valuable PET but also allows for the quantitative recovery of cotton textile waste. The catalyst’s capability to process mixed plastic waste, including polyethylene, further underscores the versatility and potential impact of this method in fostering a circular economy.

As the world grapples with the repercussions of plastic pollution, innovative solutions like this new method of PET depolymerization present a vital avenue for intervention. By promoting efficient recycling practices and enabling the recovery of useful raw materials, this development could signal a promising shift towards more sustainable waste management strategies. Ultimately, the work of Professor Nomura and his team sets the stage for a future where plastic waste is not just discarded, but transformed into economically valuable resources, paving the way for a greener, more circular economy.