In the ever-evolving field of energy storage, solid-state electrolytes are carving a niche for themselves as a safer and more efficient alternative to conventional liquid electrolytes. These advancements have the potential to revolutionize battery technology, especially as the demand for more sustainable and high-performance batteries increases. Despite the progress made over the years, significant challenges remain in enhancing the efficiency and effectiveness of solid-state materials. Researchers at the University of Illinois Urbana-Champaign have embarked on a groundbreaking journey, investigating the impact of helical secondary structures in peptide polymer electrolytes on ionic conductivity and overall stability.

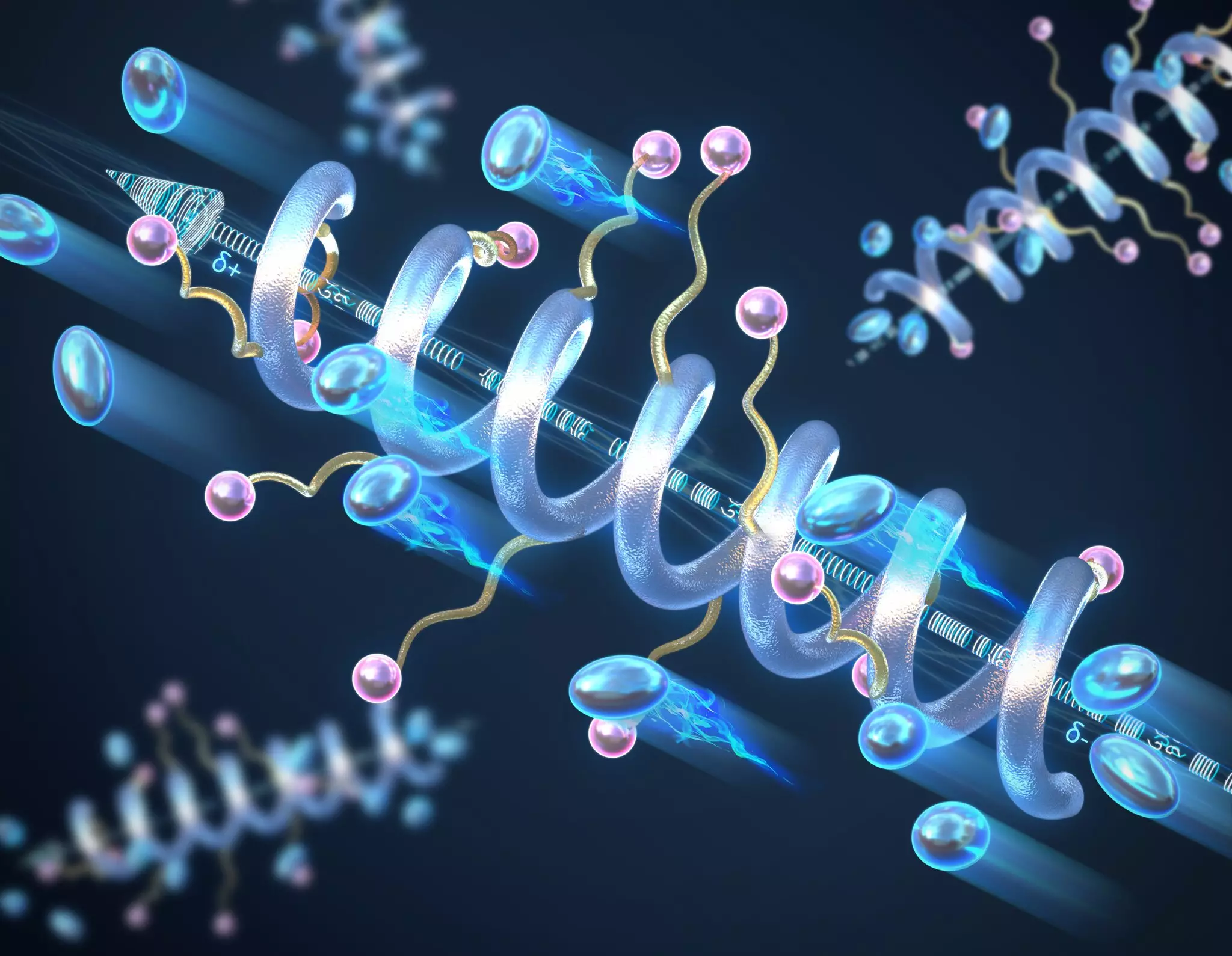

The research team investigated the properties of helical peptide structures as opposed to traditional random coil configurations in polymer designs. Polymers are typically characterized by their unpredictable alignment, leading to variances in performance. However, imbuing these materials with a helical structure—a configuration reminiscent of DNA—offers a strategic improvement in their conductive capacity. Professor Chris Evans, who spearheaded the study, emphasizes the innovation of employing biological principles to enhance material properties for non-biological applications. By organizing polymer backbones into a structured helix, researchers can create a macrodipole moment—a collective separation of positive and negative charges—resulting in significant boosts to both conductivity and dielectric constants.

The findings published in the premier journal *Nature Materials* demonstrated clear correlations between the length of the helix and ionic conductivity. Longer helical structures are associated with increased conductivity, which is crucial for battery efficiency. This effect occurs due to the cumulative impact of small dipole moments from individual peptide units, which align along the helix. The macrodipole that emerges not only facilitates charge transport but also enhances the ability of the material to store electrical energy. These enhancements mark a significant step forward in the quest for next-generation battery technologies that rely on solid-state designs.

Investigation into the thermal and voltage stability of these helical polymer electrolytes revealed substantial advantages over traditional random coil structures. The inherent robustness of the helical formation enables these materials to endure high temperatures and voltages without degradation—an issue often encountered with common polymer electrolytes. This stability translates into increased safety and reliability in energy storage applications, addressing one of the primary concerns related to battery design. Evans notes that the helical structures exhibit commendable resilience, showing no signs of breakdown before the intended lifecycle of the material expires.

An additional highlight of this innovation lies in the environmental benefits associated with peptide-based materials. Upon reaching the end of their operational lifespan, these materials can be effectively reprocessed into their individual monomer units through enzymatic or acidic means. This recyclability minimizes waste, allowing for the recovery and reuse of starting materials and thus reducing the overall environmental impact of battery technologies. By integrating sustainability into the design of energy storage solutions, researchers are creating a more responsible pathway for future innovations.

The research undertaken at the University of Illinois Urbana-Champaign exemplifies a transformative approach to solid-state electrolytes by integrating structural biology with material science. The findings underscore the potential of helical peptide polymer electrolytes to redefine performance benchmarks in energy storage, balancing high conductivity with exceptional stability. As the quest for more efficient and environmentally friendly battery technologies continues, innovations like these will play an essential role in shaping the future of energy storage systems. Future research is likely to explore further optimizations in polymer architectures and investigate the practical applications of these findings in commercial battery technologies.