Traditionally, the presence of pores or voids in materials has been regarded as a significant flaw, undermining their mechanical integrity. Researchers and manufacturers have gone to great lengths to eradicate such imperfections, believing that a homogeneous structure equates to enhanced performance. However, recent findings from a research team led by Prof. Jin Haijun at the Institute of Metal Research, part of the Chinese Academy of Sciences, challenge this conventional belief. Their exciting research suggests that voids, when strategically integrated into certain materials, can actually enhance performance rather than detract from it.

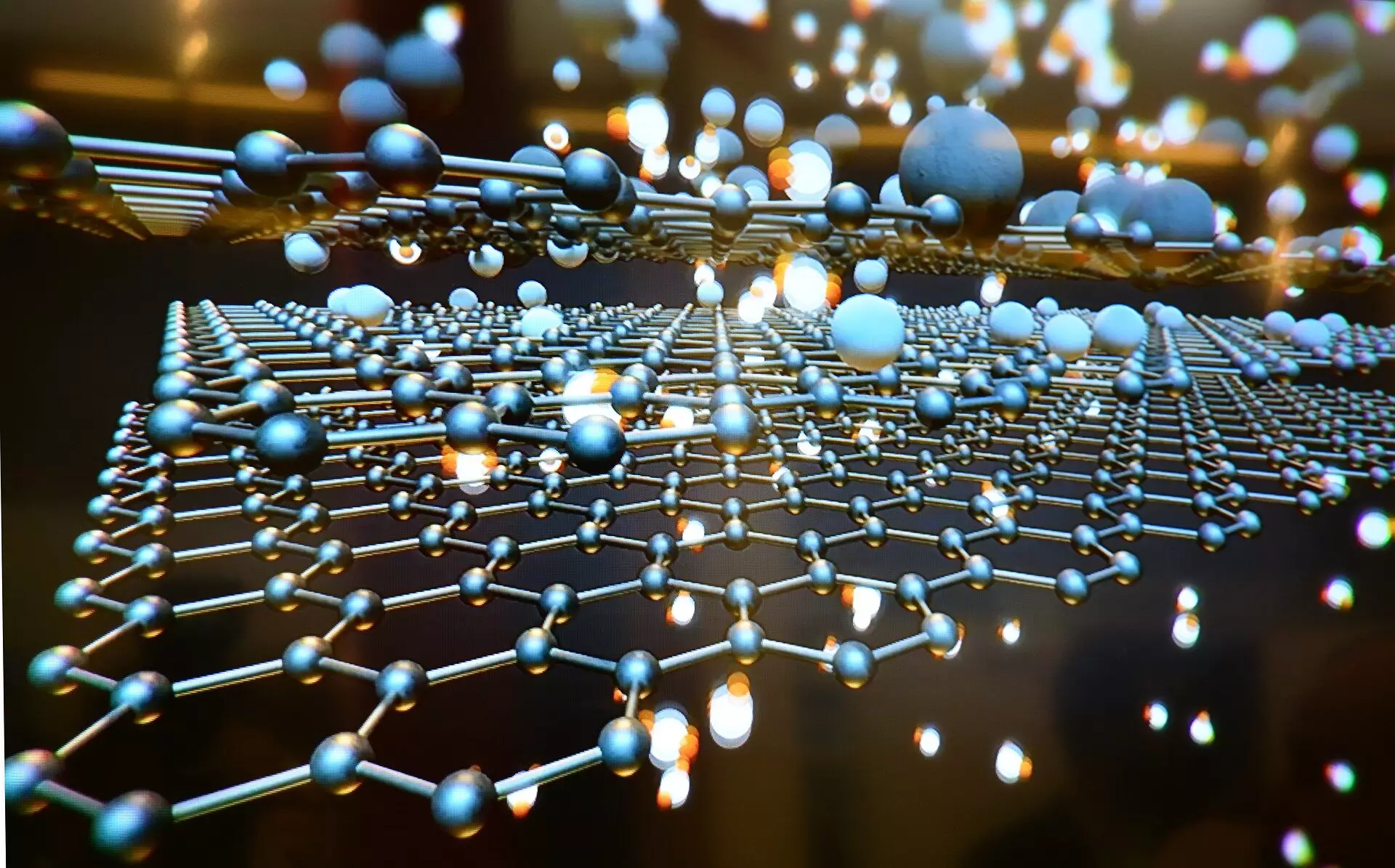

The groundbreaking work revolves around a new material known as nanovoid dispersed gold (NVD Au). Unlike standard gold, which is dense and uniform, NVD Au is engineered with numerous nanoscale voids, ranging from just a few nanometers to several hundred. These voids are not randomly scattered; they are meticulously distributed throughout the material, which significantly alters its mechanical properties. This innovative approach has illuminated pathways for material development that diverges from traditional manufacturing practices.

The creation of NVD Au involves a sophisticated blend of several processes. The team utilizes dealloying, a corrosion technique, followed by compression and subsequent thermal annealing. This combination results in a material that not only retains the excellent physical and chemical properties of traditional gold but also benefits from the unique attributes conferred by the nanovoids. The researchers revealed that this process allows NVD Au to exhibit enhanced strength and ductility, outperforming conventional dense gold in tension tests. The study’s findings were published in the esteemed journal *Science*, marking a significant milestone in materials science.

The improvements in mechanical performance can be attributed to the interaction between dislocations and the voids within the material. This unique configuration helps to suppress crack nucleation, which is a common failure point in conventional materials. Unlike larger voids, which tend to concentrate stress and compromise structural integrity, the nanoscale voids in NVD Au facilitate improved stress distribution. The result is a lightweight material capable of handling higher loads, with the additional benefit of being extendable without breaking.

The implications of this research extend well beyond the realm of academic curiosity. The enhancement of mechanical properties through void engineering presents new opportunities in various industrial sectors. From lightweight components in portable electronics to advanced materials for aerospace applications, the versatility of NVD Au presents an exciting frontier for engineers and manufacturers alike.

The pioneering work led by Prof. Jin’s team invites a reevaluation of the role of voids in materials. By shifting focus from elimination to strategic incorporation of voids, the materials science community might unlock new potential and applications, paving the way for innovative solutions in technology and manufacturing. This paradigm shift underscores the importance of ongoing research in understanding the complexities of material properties.