Piezoelectric materials are essential components in a range of modern technologies, most notably in sonar and ultrasound applications. These materials can convert mechanical energy into electrical energy, and vice versa, making them invaluable in medical imaging and underwater exploration. However, their optimal performance relies heavily on the alignment of dipoles—pairs of positively and negatively charged ions within these materials. This alignment, known as “poling,” is crucial for enhancing their piezoelectric properties. Nevertheless, factors such as heat and pressure can disrupt this alignment, leading to performance degradation. Historically, restoring piezoelectric properties required extensive and often damaging repair processes. New research has unveiled a groundbreaking method that mitigates these challenges by allowing for restoration of piezoelectric function at room temperature.

The poling of piezoelectric materials involves placing them in an external electric field, which aligns the dipoles in a uniform direction, thus amplifying their piezoelectric effect. Ferroelectric materials, which exhibit spontaneous polarization, generally require precise tuning to maintain this alignment. However, exposure to elevated temperatures—even as low as 70°C—can lead to depoling, where the dipoles lose their alignment, resulting in diminished performance. This not only makes manufacturing processes challenging but also limits the types of materials that can be employed in device construction. With traditional methods necessitating the disassembly of devices and exposure of materials to temperatures exceeding 300°C for repoling, the inefficiencies and costs associated with these techniques are significant.

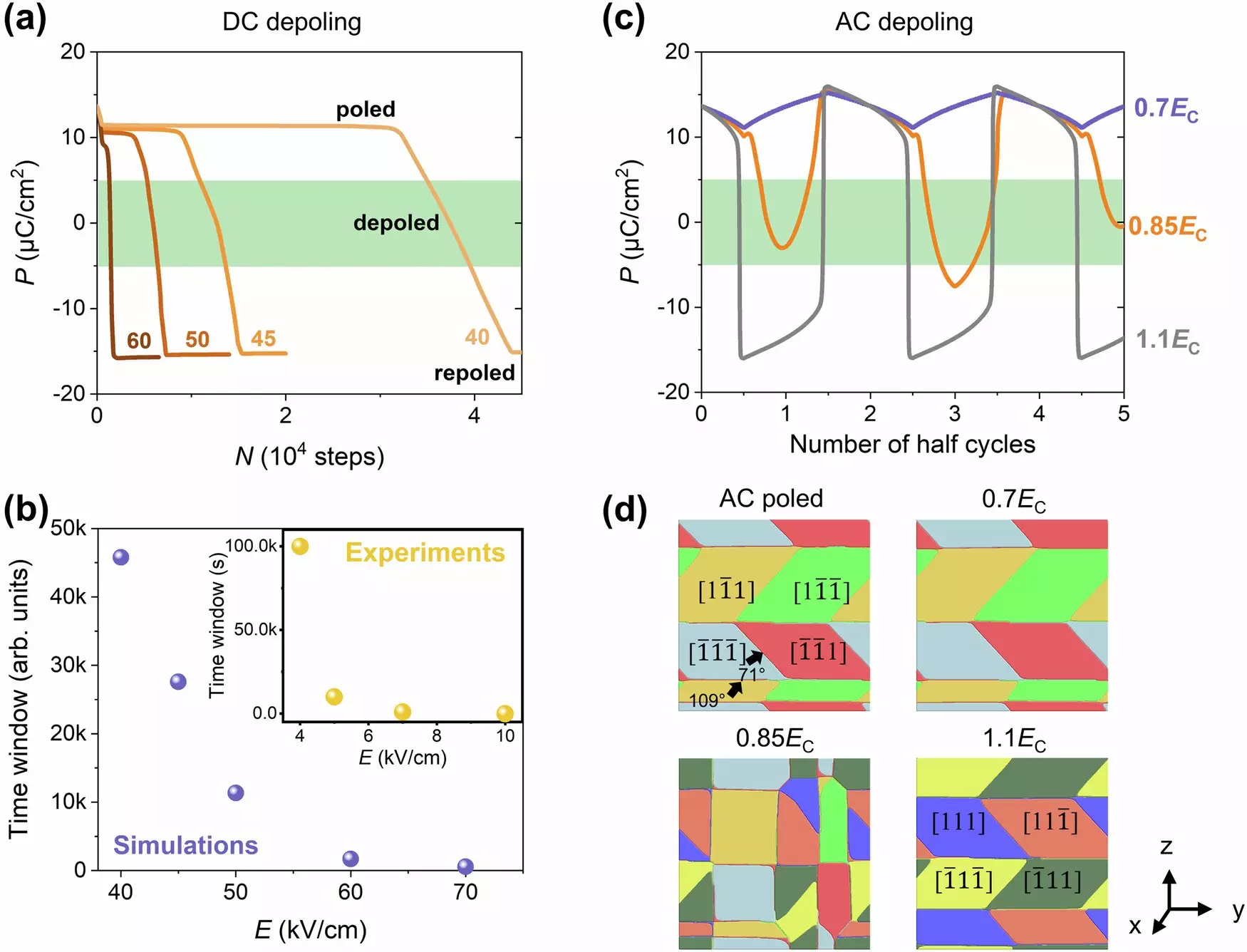

Researchers from North Carolina State University have developed an innovative technique to depole and repole piezoelectric materials without the need for high temperatures. This method allows for the realignment of dipoles at room temperature, thus simplifying the repair process. The breakthrough finding lies in the application of alternating current (AC) electric fields. Unlike direct current (DC) fields, which effectively align dipoles but are ineffective for depoling, the AC technique offers a dual advantage: it not only facilitates repoling but also allows for the significant reduction of existing dipole alignment without necessitating device disassembly or thermal treatment.

To clarify, if a piezoelectric material was initially poled using a DC field, the introduction of an AC field can significantly reduce the alignment of dipoles, while if the material was originally poled using an AC field, the alignment can be completely negated using the same method. This versatility makes the process more accessible for manufacturers and maintenance technicians alike.

The ramifications of this advancement for ultrasound and sonar technology cannot be understated. One significant advantage is the flexibility it offers in material selection during device manufacture. Previously, manufacturers had to contend with heat and pressure limitations when choosing complementary materials, often resulting in compromises in performance. With the new AC poling approach, designers have the freedom to explore more diverse components that could improve the overall functionality of ultrasound devices.

Moreover, the ability to restore piezoelectric effectiveness at room temperature opens the door for routine maintenance practices that can extend the lifespan of existing technology. This could lead to significant cost savings in medical settings, where devices are frequently used and may experience wear from prolonged use. Additionally, more efficient reuse of expensive materials could help reduce waste in manufacturing processes, aligning with broader sustainability goals.

The research published in Nature Communications signifies a pivotal advancement in the field of material science and engineering. By allowing for the room-temperature repoling of piezoelectric materials, this new technique not only streamlines the repair process but also opens avenues for innovation in product design and application. As technological demands evolve, the ability to optimize the performance of devices reliant on piezoelectric materials may in turn facilitate advancements in a variety of fields, ranging from healthcare to environmental monitoring. The future of piezoelectric materials looks promising, as they stand to become more reliable and easier to maintain, reflecting a critical stride towards more efficient and sustainable technological solutions.