In the quest for a decarbonized global energy landscape, seawater electrolysis has emerged as a promising avenue for generating hydrogen fuel. Despite its potential, several challenges impede progress in this domain. The corrosive nature of chloride ions leads to anode degradation and unwanted oxidation reactions, complicating the electrolysis process. Additionally, the high costs associated with effective catalysts limit the scalability of direct seawater electrolysis methods. Addressing these challenges is crucial for unlocking the potential of this sustainable energy source.

Recent advancements have brought self-supported nickel-iron (NiFe) materials into the spotlight as viable bifunctional catalysts for hydrogen and oxygen evolution reactions. These materials offer an appealing combination of high intrinsic activity and cost-effectiveness, making them suitable candidates for large-scale applications. Researchers have been actively exploring innovative substrates that can enhance the efficacy and durability of NiFe-based catalysts in seawater electrolysis.

One such substrate gaining traction is wood-based carbon (WC) structures. These materials are characterized by a hierarchical porous architecture that facilitates excellent conductivity and electrochemical performance. The recent work by a collaborative team of researchers, including academics from Southern University of Science and Technology, the University of New South Wales, and Curtin University, exemplifies the fusion of sustainability with advanced material science. Their studies, published in the journal *Science Bulletin*, illustrate how wood waste can be repurposed into an effective support for catalysts.

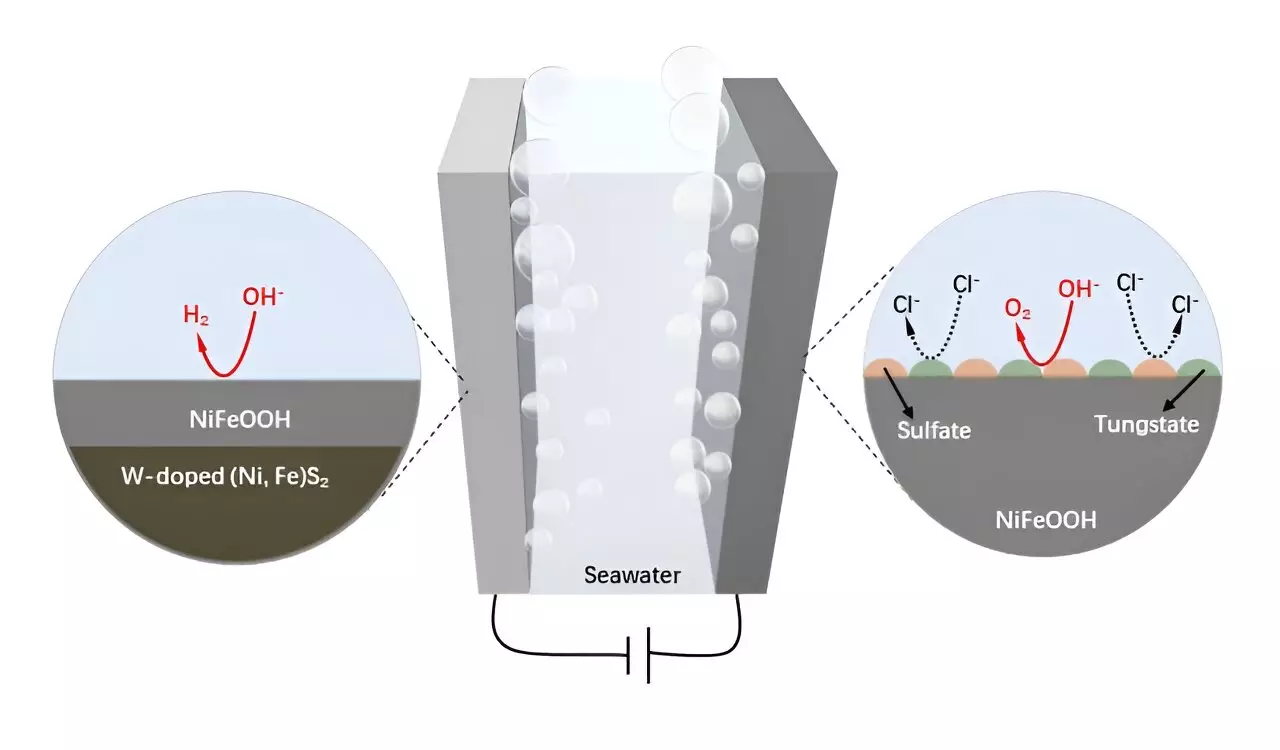

The introduction of tungsten into the NiFe catalyst has unveiled significant improvements in the anode’s anti-corrosive properties. The resulting W-doped NiFe sulfide (W-NiFeS) developed on a wood-carbon support demonstrates remarkable stability and efficiency in seawater electrolysis. Employing a specialized preparation method involving impregnation and sulfidation, the researchers successfully created a three-dimensional hierarchical structure for the electrode. This innovation resulted in densely anchored nanoparticles and superior electrical conductivity.

The novel W-NiFeS/WC electrode showcases unprecedented performance in both the oxygen and hydrogen evolution reactions within alkaline seawater, marking it as a standout compared to traditional catalysts. The study highlights the ability of the electrode to dynamically evolve, forming anti-corrosive species that further enhance its longevity and effectiveness. Zhijie Chen, the lead researcher, emphasizes that the innovative nature of this electrode could pave the way for practical applications in sustainable hydrogen production.

Beyond just providing a solution to the immediate challenges of seawater electrolysis, this research embodies the principles of a circular economy by transforming wood waste into valuable resources. This approach not only minimizes environmental impact by reducing waste but also contributes to the broader goal of sustainable hydrogen fuel production. As the need for clean energy alternatives becomes increasingly urgent, the insights gained from this study will be instrumental in developing efficient and eco-friendly energy conversion technologies.

The integration of cutting-edge materials like W-doped NiFe sulfides supported on wood-based carbon reveals a promising pathway forward for seawater electrolysis, highlighting the intersection of environmental sustainability and technological innovation.