The world is on the brink of a biomaterials revolution, where the potential of bacteria is being transformed into sustainable solutions for diverse industries. The quest for eco-friendly materials has prompted scientists to explore the capabilities of these microscopic organisms in producing substances that have significant industrial, medical, and consumer applications. From cellulose and silk to a variety of minerals, bacteria hold the key to unlocking sustainable processes that operate at ambient conditions. However, traditional methods of bacterial material production often result in yields that are insufficient for large-scale industrial use. Despite the tremendous promise, the challenge lies in augmenting bacterial efficiency to support higher outputs in shorter time frames.

Researchers are now developing strategies to enhance the production capabilities of bacteria, effectively turning them into “living factories” capable of churning out materials at an industrial scale. This endeavor involves complex genetic modifications or the strategic cultivation of optimal bacterial strains designed for high productivity. One groundbreaking study led by Professor André Studart at ETH Zurich exemplifies such innovations through the use of the cellulose-producing bacterium, *Komagataeibacter sucrofermentans*.

Advancements in Cellulose Production

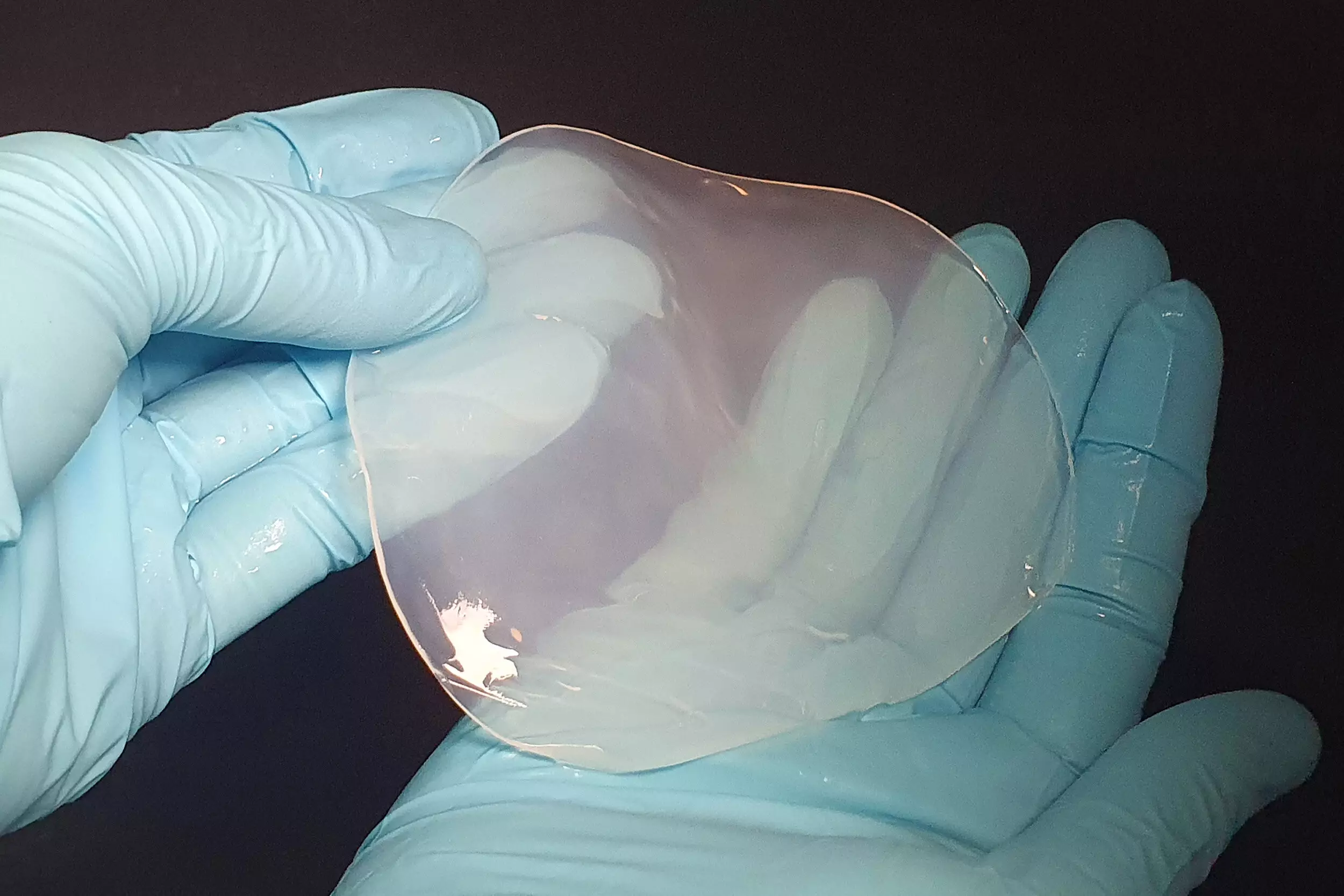

The research team discovered a novel approach inspired by natural selection that allowed them to generate thousands of bacterial variants rapidly. By manipulating the genetic material of *K. sucrofermentans*, the scientists aimed to increase its cellulose production significantly. Cellulose, a fundamental biopolymer with extensive applications, particularly in the biomedical field and packaging industries, is in high demand. K. sucrofermentans, recognized for producing pure cellulose, had previously been constrained by slow growth rates and minimal output.

Julie Laurent, a doctoral student on Studart’s team, spearheaded the initiative to enhance cellulose generation using a relatively simple technique: UV-C light irradiation. This method introduces random mutations in the bacterial DNA, enabling the generation of diverse variants. Once these cells were subjected to a controlled environment that prevented DNA repair, their subsequent cellulose production was meticulously monitored and measured.

To efficiently evaluate the efficacy of each mutant, the team implemented an innovative sorting system that could process massive numbers of samples, allowing them to isolate the most productive strains within mere minutes. The selected variants were found to produce cellulose at rates 50-70% higher than their wild-type predecessors, a remarkable achievement that could have profound implications for the material production landscape.

Unraveling Cellular Mechanisms

A significant advancement in this research is the genetic analysis of the high-producing variants, which revealed crucial insights into how these modifications impact cellulose synthesis. The identified mutations predominantly affected a gene coding for a protease—an enzyme that degrades proteins related to the regulation of cellulose production. Surprisingly, the genes responsible for cellulose synthesis itself remained unchanged. This led researchers to hypothesize that the inhibition of cellular regulation due to the protease’s activity elevates cellulose output, suggesting that unfettered cellulose production could emerge from the disruption of regulatory pathways.

The implications of this discovery extend beyond mere cellulose. The principles established through this study can be adapted to other bacterial strains and materials, paving the way for future innovations in microbial biotechnology.

Applications and Future Prospects

Armed with a patent for their pioneering method and mutated bacterial strains, Studart’s team is eager to partner with industry leaders. The potential for these enhanced bacterial variants to perform under real-world industrial conditions presents exciting possibilities. Imagine a future where factories are filled with microorganisms that crank out materials without the carbon footprint associated with traditional manufacturing methods. This vision, once confined to the realm of science fiction, is now within reach—the key lies in leveraging the inherent capabilities of these microorganisms.

In a timeline where climate change and resource scarcity demand immediate and innovative responses, the use of bacteria as sustainable production agents can significantly contribute to a circular economy. With continued research, the transformation of bacteria into commercial biologically-based materials could disrupt existing paradigms in material science, offering eco-friendly alternatives to conventional production methods.

As this research progresses, one can only hope that the leap from laboratory experiments to widespread industrial application occurs rapidly, allowing bacteria to emerge as a cornerstone of sustainable manufacturing solutions. By harnessing nature’s ingenuity, scientists like André Studart and Julie Laurent are not merely exploring new scientific frontiers but also paving the way for a greener, more sustainable future.