The ongoing transition to renewable energy sources marks a pivotal moment in our global effort to ensure a sustainable future. However, harnessing energies like solar and wind comes with intrinsic challenges, particularly in the realm of energy storage and conversion. A key methodology in this area is water electrolysis, specifically through alkaline water electrolysis systems (AWEs). These systems, already noted for their cost-effectiveness and durability, face significant hurdles related to intermittent energy supplies. As fluctuating weather patterns disrupt energy generation, the efficiency of these electrolysis systems diminishes, leading to potential degradation of critical parts, namely the electrodes.

A Novel Solution: The Lead-Coated Nickel Catalyst

A recent study from a multidisciplinary team, spearheaded by the distinguished Professor Jeong Woo Han and comprising researchers from Pohang University and Seoul National University, introduces an innovative resolution to these challenges. By employing a simple lead (Pb) coating on a nickel (Ni) catalyst, the team uncovered a dual-benefit approach that enhances durability and efficiency during the hydrogen evolution reaction (HER). Despite lead’s traditional reputation as an ineffective catalyst in this scenario, its new role proves transformative; it assists in both improving reaction kinetics and strengthening the resilience of the electrodes against reverse current-induced damage.

The key insight is that lead’s presence can catalyze not just proton desorption but also water dissociation, essential processes for improving overall hydrogen production efficiency. This breakthrough is striking—it illuminates how existing materials can be re-envisioned to overcome historical limitations.

Enhanced Resilience to Reverse Currents

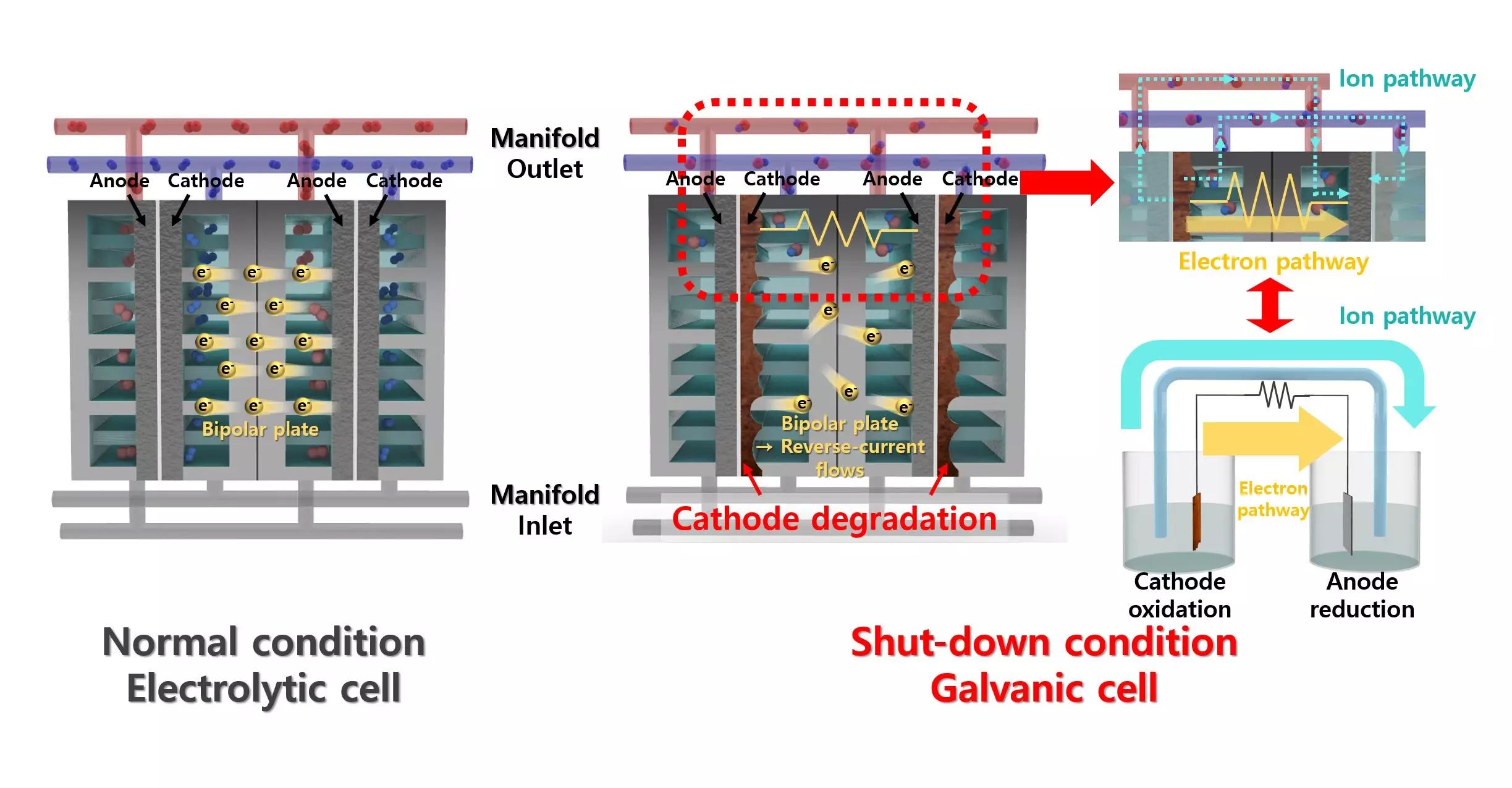

One standout feature of this new catalyst is its robust response to reverse currents, which are typically notorious for compromising the integrity of electrolyzers. In conventional AWE systems, these reverse currents can significantly shorten the lifespan of electrodes, requiring additional equipment and resources to mitigate the damage. However, this newly developed lead-coated nickel catalyst shines in its simplicity and effectiveness. The research demonstrated that the catalyst exhibits exceptional resilience through repetitive oxidation reactions, managing to withstand the pressures imposed by the starting and stopping cycles typical in AWEs.

It challenges the status quo of catalyst development where the focus is often solely on enhancing efficiency ignoring the durability aspect. By providing a holistic solution to both efficiency enhancement and structural robustness, this catalyst stands to reshape how we approach the design of electrolysis systems in renewable energy applications.

The Future of Green Hydrogen Production

The potential implications of this research are profound, not just in boosting hydrogen production but in driving down the overall costs associated with sustainable energy systems. As countries and organizations scramble to meet stringent climate goals, innovations like this lead-coated catalyst could become foundational to realizing national and global carbon neutrality targets. The work of Professor Yong-Tae Kim and his colleagues represents a significant leap forward, emphasizing that effective solutions do not always require intricate technology or exorbitant materials.

The convergence of these tangible advances in materials science and our broader energy policy ambitions could pave the way for a cleaner, more sustainable future. There’s a compelling narrative here: one of resilience, innovation, and the nascent potential of hydrogen as a clean energy carrier.