As the world grapples with the urgent challenges posed by climate change, green hydrogen emerges as a beacon of hope. With its potential to significantly reduce carbon dioxide emissions, particularly in industrial applications, this renewable energy source could transform our energy landscape. The U.S. Department of Energy is pinning its hopes on green hydrogen as a cornerstone for achieving net-zero emissions. However, the road to effective green hydrogen production is paved with scientific hurdles, particularly in the realm of electrolysis—the process by which water is split into its basic components of hydrogen and oxygen.

Understanding Electrolysis and Its Challenges

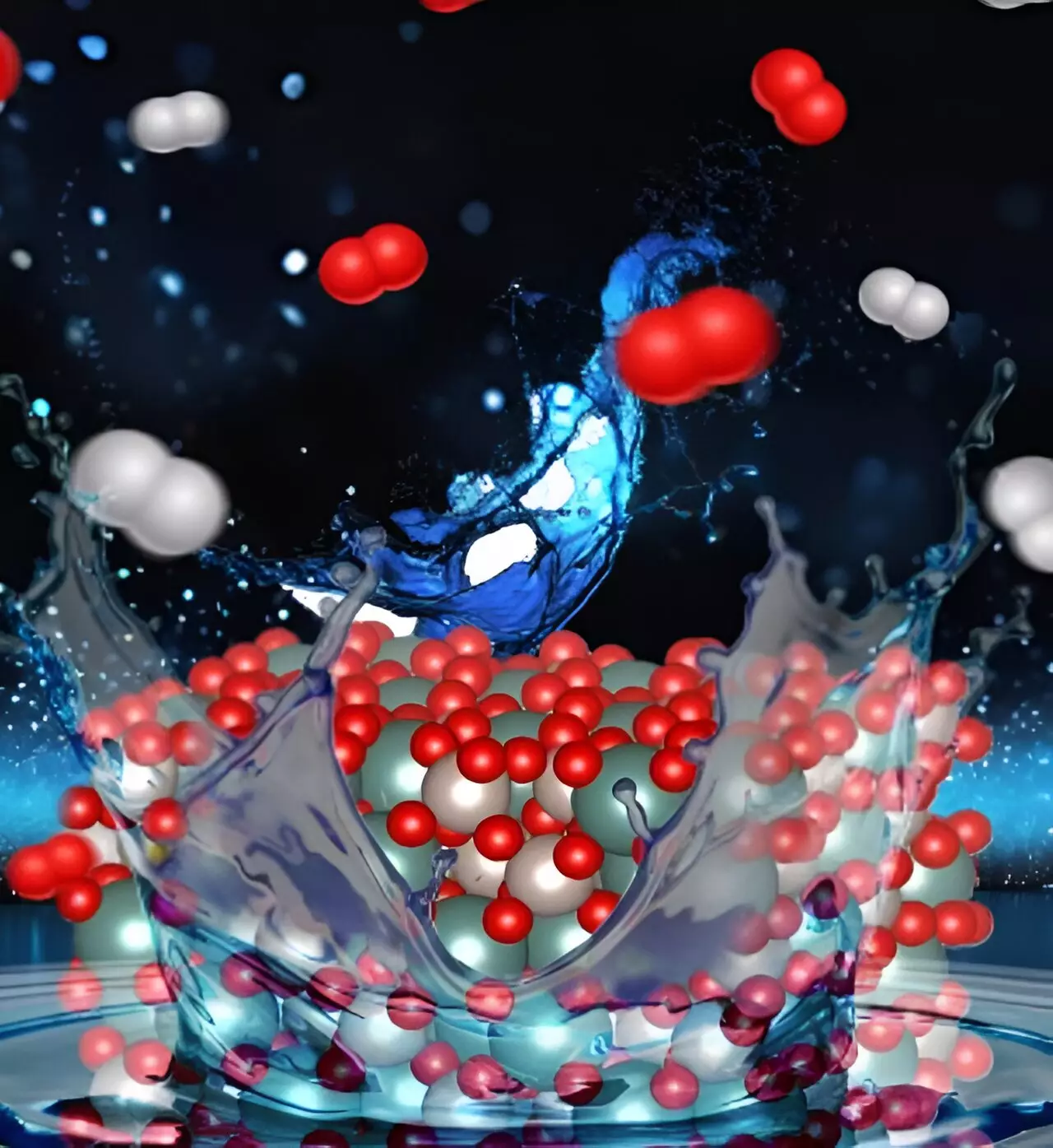

Electrolysis, typically performed using proton exchange membrane electrolyzers, effectively converts water into hydrogen and oxygen gases. While the generation of hydrogen gas occurs rapidly at the cathode, the corresponding production of oxygen at the anode lags significantly. This disparity creates a bottleneck in the process, limiting the overall efficiency of hydrogen generation. In essence, the production of hydrogen is hampered by the slower generation of oxygen, stifling the potential for scalable, cost-effective green hydrogen solutions.

This inefficiency presents a formidable challenge. It’s not enough to generate hydrogen quickly; the overall process must achieve a harmonious balance between the rates of both gas productions. Fortunately, recent advancements in catalyst design offer promising solutions to streamline this process.

Defect Engineering: A Game-Changer in Catalytic Efficiency

A groundbreaking study published in the Journal of the American Chemical Society highlights an innovative approach to enhance catalytic efficiency through a technique known as defect engineering. An interdisciplinary team of researchers, led by Professor Hong Yang, has demonstrated how the introduction of controlled imperfections into a catalyst can dramatically improve its performance. This novel methodology, while unconventional in the field of electrocatalysts, has parallels in semiconductor technology where impurities are intentionally introduced to enhance conductivity.

The researchers focused on a new complex oxide material based on ruthenium, a transition metal known for its catalytic properties. By integrating yttrium into the ruthenium structure, they created a modified catalyst that exhibited superior performance in oxygen generation. The addition of yttrium into the lattice not only influenced the electronic properties of the catalyst but also optimized the reaction kinetics at the electrode.

Quantifying Success: Rethinking Reaction Mechanisms

The research team employed sophisticated analytical techniques, including thermogravimetric analysis, to quantify the effects of these engineered defects. The findings were revelatory: the activity of the electrocatalyst increased not due to a change in the quantity of oxygen available but rather because of alterations in the oxidation state of ruthenium. This insight paves the way for a more nuanced understanding of how electrocatalysts can be designed for specific applications, challenging the traditional notion of merely maximizing active sites.

Gradate student Bidipta Ghosh, who played a pivotal role in the research, noted their surprising findings regarding the stability of oxygen concentrations even as the reaction efficiency improved. This challenges pre-existing assumptions and emphasizes the importance of a detailed investigation into the electronic transformations that occur at the atomic level.

The Importance of Interdisciplinary Collaboration

A salient point of the research is the enormous value derived from the diverse expertise of the team. This collaborative dynamic enabled them to tackle various technical challenges, underscoring the necessity for interdisciplinary efforts in scientific research. The success of their innovative catalyst design is not merely a testament to the vision of a single researcher but a culmination of knowledge across multiple fields.

As Yang aptly noted, enhancing an electrocatalyst isn’t simply about introducing imperfections; it demands a precise understanding of which types of defects yield optimal performance. The ability to control and fine-tune these defect levels is critical for advancing the efficiency of electrocatalysts on a commercial scale.

Looking Ahead: The Future of Green Hydrogen Technology

The implications of this research extend beyond the immediate objective of producing green hydrogen at lower costs. By refining the principles of defect engineering, the team sets a crucial precedent for future developments in electrochemical energy systems. This innovative approach not only promotes a greener future but also challenges the scientific community to rethink existing paradigms in catalyst design.

As industries continue to search for sustainable energy sources, breakthroughs like these will be vital in shaping a resilient energy ecosystem where green hydrogen can play a transformative role. The quest for high-efficiency catalysts is a promising path forward, paving the way for innovative solutions in the renewable energy arena.