Steel and aluminum have long been the cornerstones of the materials used in construction and manufacturing. At incredibly high temperatures, steel melts, while aluminum’s vulnerability to corrosion when exposed to moisture and oxygen limits its utility in harsh environments. Although these conventional alloys perform adequately in everyday settings, they are ill-equipped to withstand the rigors of extreme conditions such as those found in space exploration or arctic expeditions. As the frequency of operations in these extreme environments increases, there is an urgent demand for advanced alloys that can maintain structural integrity and functionality under challenging thermal and mechanical stresses.

Introducing Multi-Principal Element Alloys (MPEAs)

This emerging frontier in materials science is represented by Multi-Principal Element Alloys (MPEAs). Unlike traditional alloys made predominantly of one or two elements, MPEAs incorporate multiple elements in nearly equal ratios. This diversification creates alloys characterized by superior strength, hardness, and toughness across a spectrum of temperatures. Moreover, MPEAs are notable for their impressive resistance to corrosion and thermal degradation, making them increasingly attractive for aerospace, military, and other high-demand applications. The unique functional properties of these alloys, including their usefulness in electronic and magnetic devices, further underscore their potential.

Accelerating Innovation with Advanced Research Techniques

Researchers from the Johns Hopkins Applied Physics Laboratory (APL) are pioneering advancements in the design and synthesis of MPEAs. The team is rolling out an innovative framework to create complex microstructures that can derive significant compositional insights from a limited number of samples. Their approach hinges on linking different alloy phases—distinct materials formed during heating or cooling processes—to their mechanical properties in an automated manner. This novel pathway facilitates the synthesis of new MPEA compositions, showcasing a strategic leap forward in material development that could revolutionize how we approach material science.

Data-Driven Approaches to Material Discovery

To refine the selection of optimal MPEA compositions, APL has collaborated with researchers from the Whiting School of Engineering at Johns Hopkins University. These partnerships have produced a physics-informed Bayesian optimization algorithm known as PAL 2.0, which effectively narrows down alloy possibilities. Remarkably, PAL 2.0 demonstrates that even a modest dataset of about a dozen data points can yield substantial predictive power for alloy properties, a departure from conventional methods requiring extensive databases.

This closed-loop cycle of creation and analysis built into their research model is a major advancement. As noted by program manager Morgan Trexler, the iteration process utilises feedback from alloy testing to improve the algorithm’s recommendations continuously. By streamlining the development pipeline, researchers can now generate insights that would otherwise require extensive manpower and resources.

Innovative Synthesis Methods Enhance Composition Variety

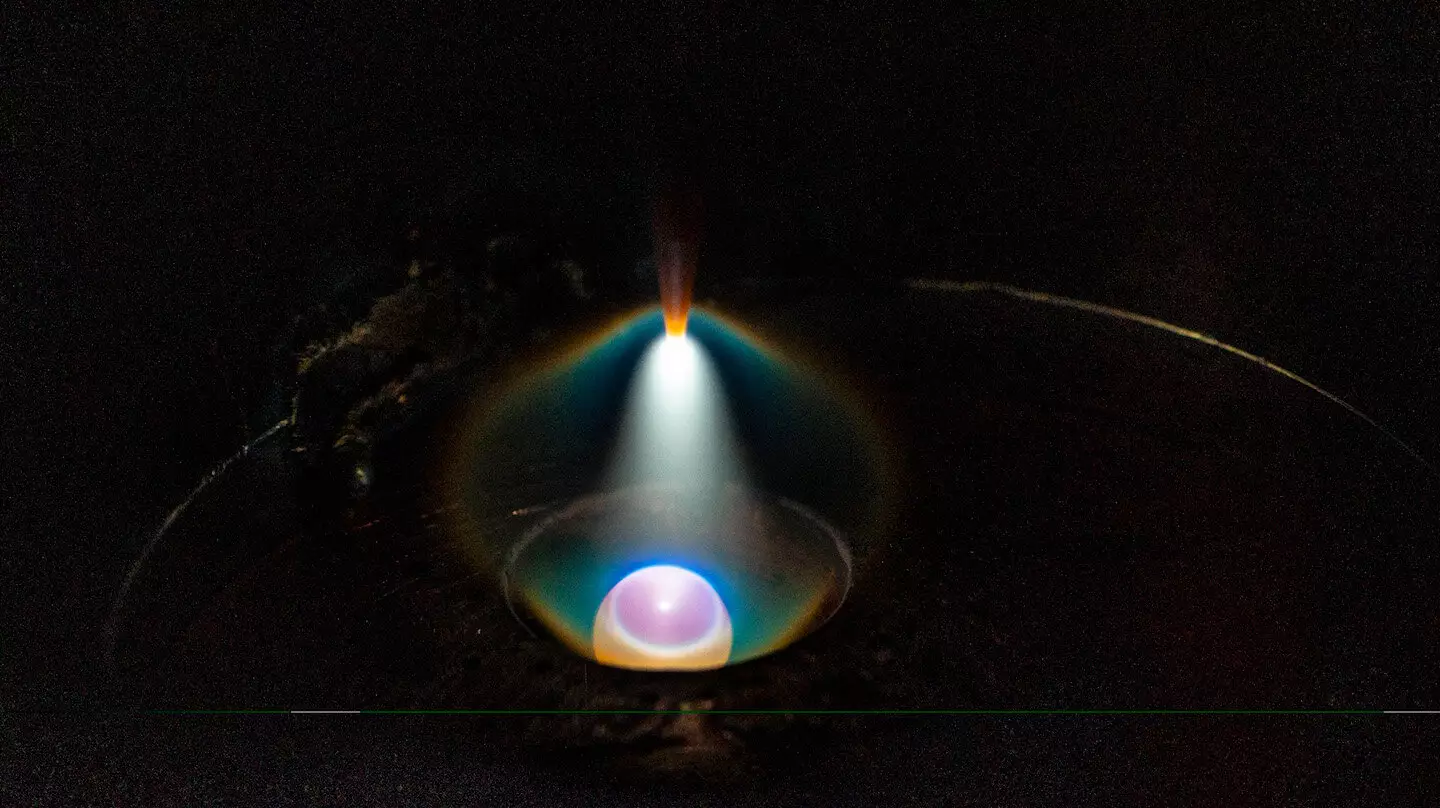

The synthesis process for these new alloys poses its own set of challenges. One compelling technique employed by APL is arc melting, which efficiently melts metal using an electrical current, allowing a vast array of compositions to form within a single sample. This method minimizes material usage while maximizing the variety of chemical compositions created in each trial. Such diversity enhances the likelihood of discovering rare and potentially groundbreaking material combinations suited for extreme conditions.

Advanced measurement techniques, such as scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDS), further support these efforts. They provide crucial data on phase compositions, while nanoindentation offers a granular assessment of hardness. By mapping measurements to specific phases, researchers can derive actionable insights into how different microstructures will behave under stress. Lisa Pogue, an APL materials scientist, emphasized that identifying undiscovered phase regions opens new possibilities in material development that could yield vital breakthroughs in the years to come.

A Comprehensive Database for Future Exploration

With a remarkable dataset consisting of over 7,000 data points and 17 distinct MPEA compositions, APL is establishing a valuable database that will serve as a foundation for future material innovation. By elucidating the parameter space for these alloys, researchers can strategically approach the design of MPEAs that exhibit desired mechanical properties, such as enhanced hardness and durability.

As highlighted by the APL research team, this multifaceted approach harnesses the synergy between advanced data analysis, machine learning, and innovative material synthesis techniques. The ability to fine-tune compositions and rapidly iterate on findings positions APL as a leader in the quest for materials that can redefine our limits in extreme environments, reinforcing the notion that we are only scratching the surface of what is possible in materials science.