In the realm of material science, unlocking the atomic-level secrets of crystalline structures has long been a tantalizing goal for researchers. A groundbreaking method utilizing atom probe tomography (APT) is creating ripples of excitement among scientists, allowing them to explore the intricate atomic relationships in materials like advanced steels and custom silicon. This innovative approach, spearheaded by researchers at the University of Sydney, opens new avenues for enhancing material properties and behavior.

The insights from this research could be a game changer, particularly in industries where the strength, weight, and energy efficiency of materials are crucial. With the proliferation of technologies demanding next-level materials—from aerospace applications to modern electronics—the implications of this study cannot be overstated. The detailed understanding of short-range order (SRO), a concept integral to material property performance, is being effectively mapped out for the first time.

Understanding Short-Range Order: A Key to Material Design

At the heart of this research is the exploration of short-range order—the local atomic configurations within crystalline materials. To put this into perspective, think of SRO as the atomic-level equivalent of a neighborhood layout; how atoms arrange themselves can dramatically affect the material’s overall behavior. For instance, variations in local atomic arrangements can influence electrical conductivity, magnetic susceptibility, heat resistance, and more.

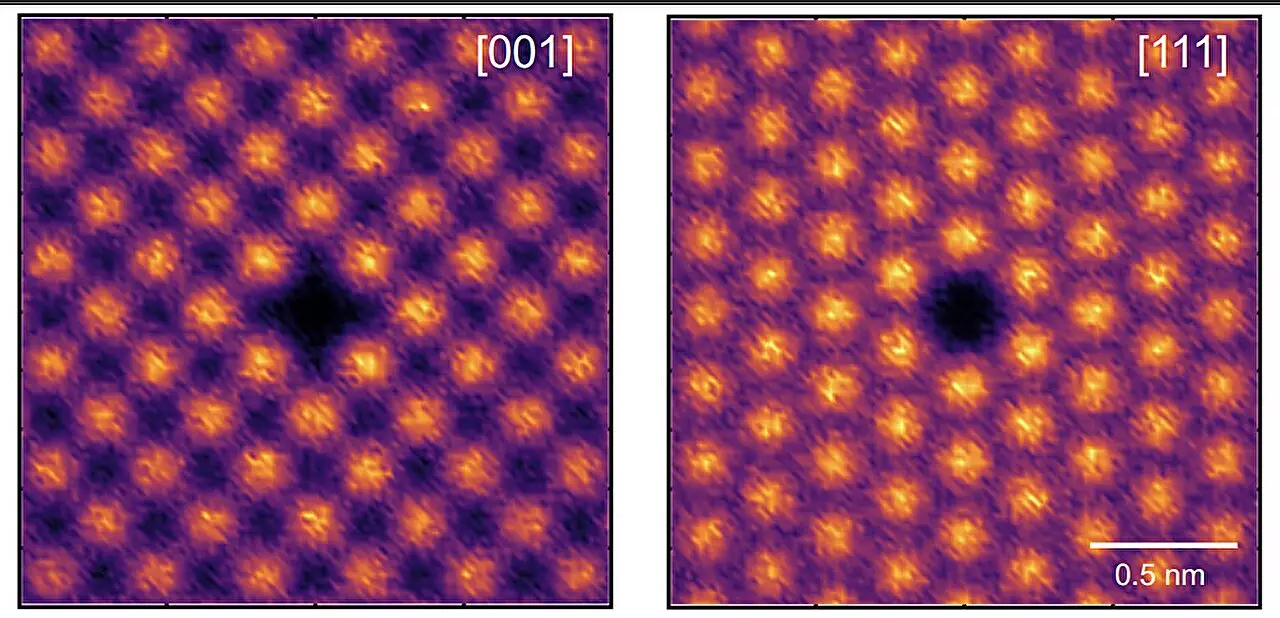

Historically, measuring and quantifying short-range order has posed significant challenges due to the incredibly small scales at which these atomic arrangements occur. Traditional microscopy techniques often fall short in capturing the nuances of these configurations. However, the innovative APT method introduced by Professor Simon Ringer and his team changes this narrative, allowing researchers to visualize and analyze these crucial atomic relationships with unprecedented clarity.

Significance for Industry Applications

The applications of this newfound understanding extend far and wide, particularly in the aerospace and electronics industries. Advanced alloys and semiconductors that leverage insights from SRO could lead to aircraft hulls that are not only lighter but also stronger, thus improving fuel efficiency and safety. In the realm of electronics, next-generation semiconductors engineered with precise atomic layouts could revolutionize performance, leading to faster, more efficient devices. The ability to systematically tailor material properties atom by atom is transforming how engineers think about and design materials.

Professor Ringer emphasizes this potential: “We are moving beyond the conventional notions of crystal structure to explore deeper atomic neighborhood relationships, enabling the custom design of materials whose properties are fine-tuned for specific applications.” The outcome is promising: stronger materials that can withstand extreme conditions, such as those found in jet engines or nuclear reactors, opening doors to revolutionary engineering solutions.

A Breakthrough in Research Methodology

The study employs advanced data science techniques alongside APT to delve into the effects of varying processing conditions on the short-range order of materials. For instance, experimenting with cobalt-chromium-nickel high entropy alloys has provided valuable data concerning how heat treatments can manipulate local atomic environments. These results serve not only as case studies but also set a benchmark for future material designs and experiments.

As Dr. Mengwei He, a key contributor to the research, noted, the ability to delve into SRO transforms material design processes. The newfound clarity promises practical applications in creating alloys that perform exceptionally under stress while minimizing weight—a dual advantage that engineers strive to achieve. Such advancements could redefine performance expectations across multiple high-stakes industries.

Challenges and Future Directions

While the research marks significant progress, it is by no means the last word in understanding material behavior at the atomic level. The task of measuring SRO remains complex, requiring ongoing refinement and exploration. According to Dr. Andrew Breen, mapping the precise boundaries within which SRO measurements hold validity presents a cautious yet optimistic pathway for future studies. The established foundations pave the way for extensive computational models that can predict material behavior, linking atomic architecture directly to macroscopic properties.

The dynamics of multicomponent alloys and their interplay with SRO present fertile ground for exploration in further studies. As researchers dive deeper into these materials, the implications of their findings could lead to a profound shift in engineering strategies across various sectors.

As scientists like Dr. Will Davids step into the industry, translating these breakthroughs from academic research into practical engineering solutions promises to enhance not just the material sciences landscape but the very fabric of technology as we know it. The ongoing journey of discovery in SRO measurement and material design is fraught with challenges but undoubtedly ripe with potential, forging a path toward a future of remarkable advancements built on the atomic-level understanding of the materials we often take for granted.