Catalysts play a pivotal role in the synthesis of over 90% of the chemical compounds utilized in various industries, particularly in everyday products. They function as accelerators that facilitate chemical reactions, often lowering the energy expenditure required for these processes. In many cases, certain reactions would be virtually impossible without the presence of a catalyst, highlighting their significance. As industries strive for efficiency and sustainability, the need for more effective catalyst technologies becomes increasingly urgent.

Recent advancements by researchers at the Karlsruhe Institute of Technology (KIT) have ignited hope in the quest for more sustainable catalytic processes. Their work focuses on noble-metal catalysts, which are extensively employed in the chemical sector due to their effectiveness. The researchers have proposed an innovative concept that enhances the stability of these catalysts while significantly reducing the amount of noble metal used in their synthesis. This reduction is a crucial step toward more sustainable practices in resource utilization and economic feasibility.

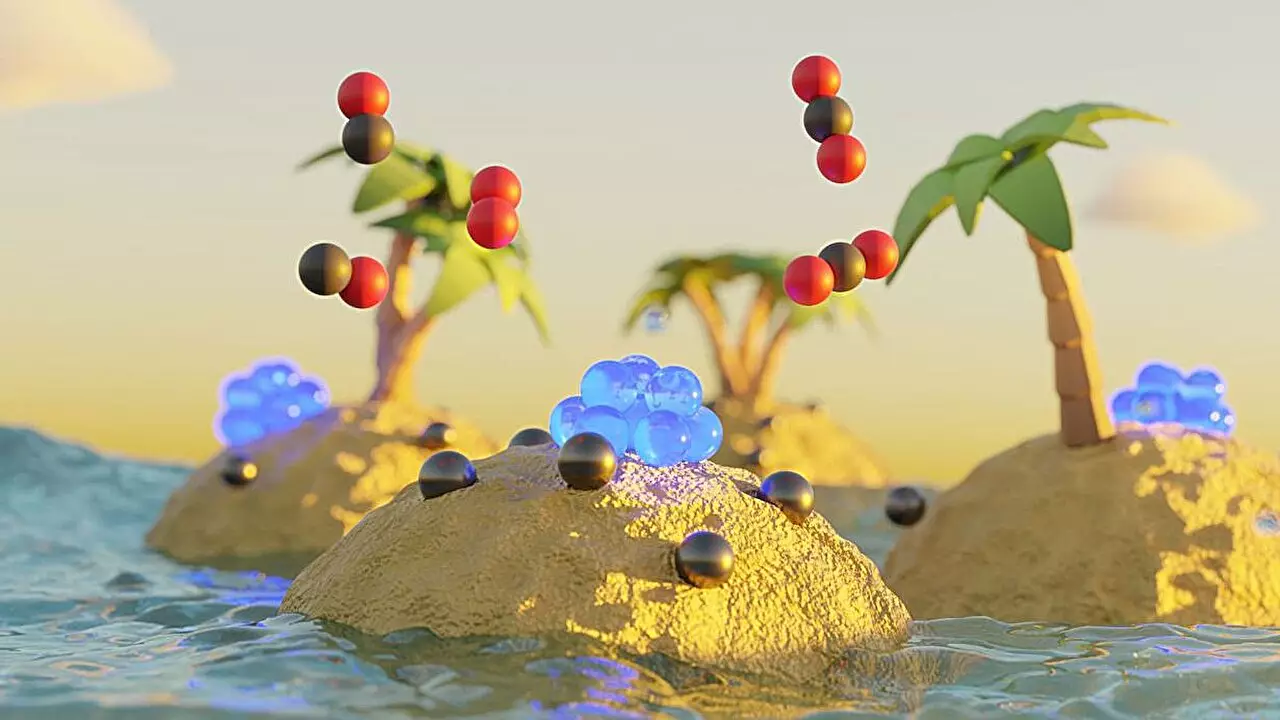

The crux of this research lies in a meticulous examination of supported catalysts at an atomic level. Traditionally, supported catalysts comprise tiny nanoparticles of noble metals dispersed on a support material where reactions occur. These nanoparticles are dynamic entities, undergoing structural changes in response to varying reaction conditions. They may coalesce into larger particles, which diminishes the availability of surface atoms that facilitate reactions, or they can fracture into isolated atoms that lack catalytic efficiency. Such behaviors can significantly impede performance, making it essential to understand and manage these dynamics effectively.

The novel approach pioneered by the KIT researchers tackles these challenges by strategically manipulating the interactions between noble metals and their support materials. By optimizing these interactions, the team has been able to develop a catalyst that not only maintains its stability over prolonged usage but also fosters the formation of active noble metal clusters, even when the quantity of noble metal is minimal. Dr. Daria Gashnikova, the lead author of the study, underscores the potential of this method to revolutionize catalyst performance, paving the way for more efficient chemical processes.

The findings from this research, published in the esteemed journal Angewandte Chemie, have profound implications for the future of chemical production. As industries increasingly confront the challenges of resource scarcity and environmental impact, optimizing the use of noble metals in catalysts aligns with broader sustainability goals. By producing robust catalysts that require less precious material, this research not only reduces costs but also contributes to a more sustainable model of resource consumption. Ultimately, the innovation showcased by KIT represents a significant leap forward in the field of catalysis, promising transformative changes in the chemical industry for years to come.