In the ever-evolving landscape of material science, the integration of photonics and nanotechnology has birthed remarkable innovations. Recent research highlights groundbreaking advancements where gold nanorods are embedded within hydrogels, yielding structures that not only adapt to light but can also be precisely controlled through 3D printing. This transformative capability paves the way for smart materials designed for various applications, including robotics, biomedical devices, and even responsive consumer products.

The Science Behind the Magic

The premise of this research merges two critical material sciences: hydrogels and nanotechnology. Hydrogels, composed of water-absorbing polymers, have been pivotal in various industries, from medical applications to agriculture. They possess the unique ability to absorb significant amounts of water, which enables them to change shapes and properties in response to environmental stimuli.

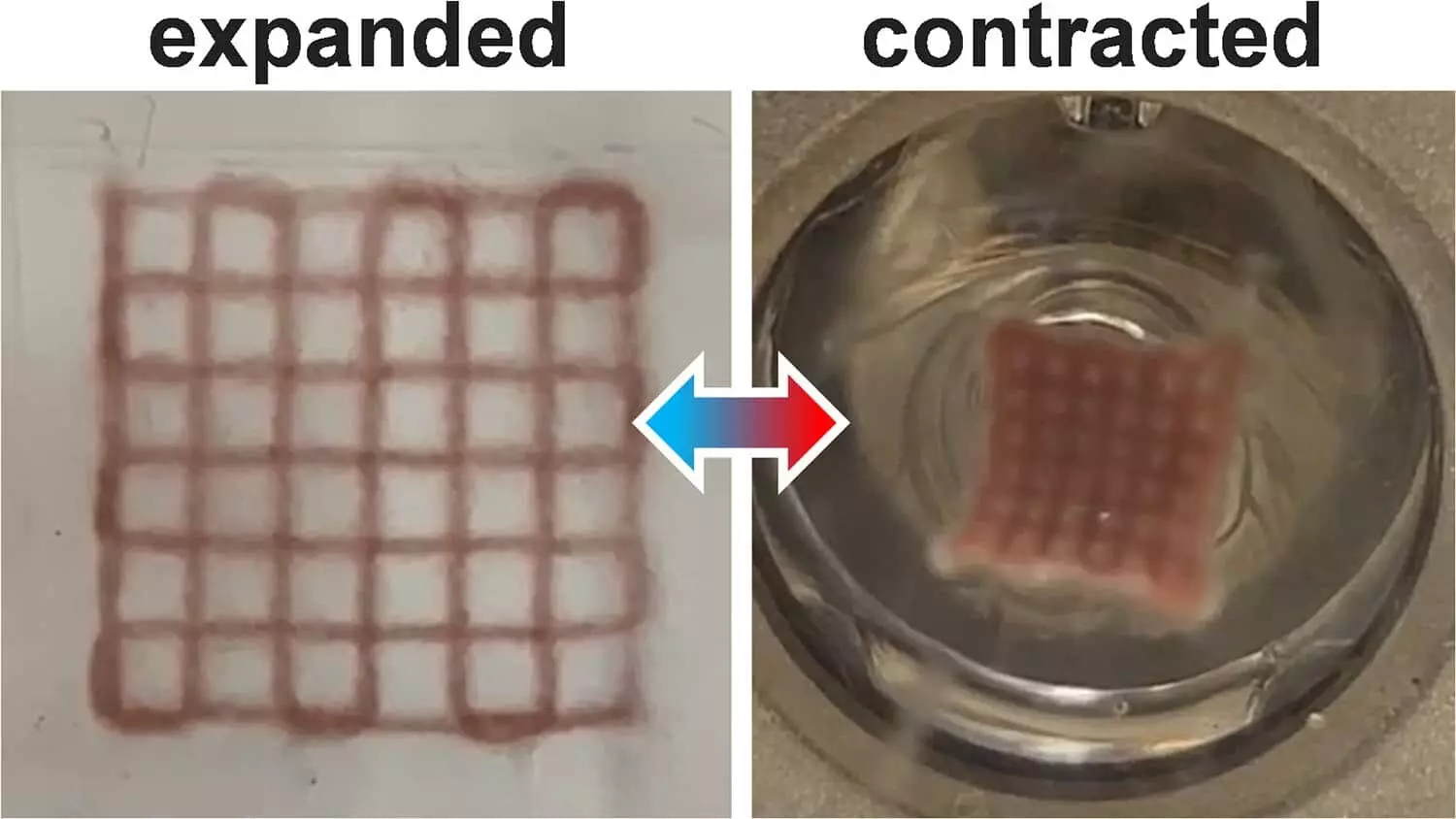

In this innovative approach, researchers have cleverly introduced gold nanorods into these hydrogels. When exposed to light, these nanorods absorb electromagnetic radiation, converting photons into localized heat. This heating initiates a contraction of the hydrogel matrix, making it a dynamic entity capable of reversible transformations. The importance of this thermally-induced contraction lies in its rapid, responsive behavior, opening doors to new applications across multiple fields.

3D Printing: A Game Changer for Material Fabrication

What sets this research apart is the employment of 3D printing technology to fabricate these hydrogel structures. Traditional methods of molding hydrogels can limit design flexibility, stifling innovation. However, the ability to 3D print hydrogels allows for intricate designs and complex geometries that were previously unattainable. This technological leap not only democratizes the design process but also enhances functional versatility, enabling the creation of customized shapes tailored for specific applications.

The researchers tackled significant challenges inherent in 3D printing hydrogels, notably the low viscosity of pre-hydrogel solutions. By mixing these solutions with gelatin microparticles in a translucent slurry, the team devised a method to maintain structural integrity during the printing process. The gelatin serves as a temporary support matrix, allowing for precise layer deposition while facilitating the subsequent polymerization process. The ingenuity behind this approach highlights the critical intersection of chemistry, engineering, and design.

Applications: From Robotics to Medicine

With its unique characteristics, this technology redefines what is possible in the realm of actuators and responsive materials. One potential application lies in the field of soft robotics, where soft actuators that mimic biological movements are becoming increasingly relevant. Robots that adapt their shape or movement in real-time could be game-changers in scenarios ranging from search-and-rescue missions to delicate surgeries.

In medicine, these light-responsive hydrogels hold promise for drug delivery systems. Imagine hydrogel-based implants that release therapeutic agents only in response to specific light frequencies, thereby minimizing side effects and enhancing treatment efficacy. This ability for precise control over drug release could significantly improve patient outcomes in chronic disease management.

Challenges and Future Directions

Despite the optimism surrounding this discovery, certain challenges remain. Researchers must navigate issues related to material durability, biocompatibility, and scalability of production methods. As promising as this technology appears, thorough testing and validation are necessary before widespread implementation.

Furthermore, the integration of other stimuli-responsive materials could amplify the functionality of these hydrogels. Future innovations could see hybrid systems that respond to environmental challenges like temperature, pH, or mechanical stresses, thereby embedding intelligence into everyday objects.

The creation of 3D printed hydrogels with embedded gold nanorods marks a significant milestone in material science. By harnessing light to control the physical properties of hydrogels, researchers are not merely developing new materials; they are redefining the boundaries of material capability. As exploration continues, it promises to stimulate further innovations that will likely change the fabric of technology and its applications across various industries, all while adding a layer of intelligence and adaptability to the materials we use every day.