The advancement of biomedical science often hinges on the ability to mimic the complex characteristics inherent in human tissues. Materials that can flexibly replace or repair damaged body parts remain an elusive goal. A remarkable new technique has emerged from CU Boulder and the University of Pennsylvania, which aims to revolutionize this field by enhancing the elasticity and strength of 3D printed materials, thus paving the way for innovative medical applications.

Existing Challenges in Biomaterial Development

Traditional biomedical devices have relied heavily on methods such as molding and casting. Though effective for mass production, these techniques fall short when personalized medical solutions are needed. Patients each have unique anatomical requirements, and solutions tailored to those individual specifications are critical for successful outcomes. As various tissues in the body present different mechanical properties—such as elasticity in cardiac tissues versus the sturdiness required in cartilage—therapies must account for these variances.

The need for materials that can mimic the natural characteristics of these tissues is crucial, especially since damaged cardiac and cartilage tissues possess a very limited capability for self-repair. This has led researchers down the avenue of 3D printing, which permits the creation of bespoke implants designed for individual patients. However, many current 3D printing methods fail to produce materials that meet the unique demands of living tissues, often resulting in products that are either too brittle or too stiff.

A Breakthrough in Printing Technology

In a landmark paper published in the journal *Science*, researchers led by Jason Burdick have developed a novel printing methodology known as CLEAR (Continuous-curing after Light Exposure Aided by Redox initiation). This new technique addresses challenges associated with producing functional hydrogels—materials that are essential for developing artificial tissues and organs. The strategic incorporation of entangled molecular structures, inspired by the natural behavior of certain worms, improves the toughness of these hydrogels while retaining their necessary flexibility.

Historically, hydrogel materials struggled to maintain their integrity under stress, leading to a high rate of failure in real-world applications. The CLEAR technique resolves this issue by enabling the material to sustain significant stress and strain, effectively allowing it to adapt to the dynamic movements of the tissues it is designed to support. For instance, the new hydrogels can withstand repetitive stresses akin to those encountered by the heart and joints throughout their lifetime.

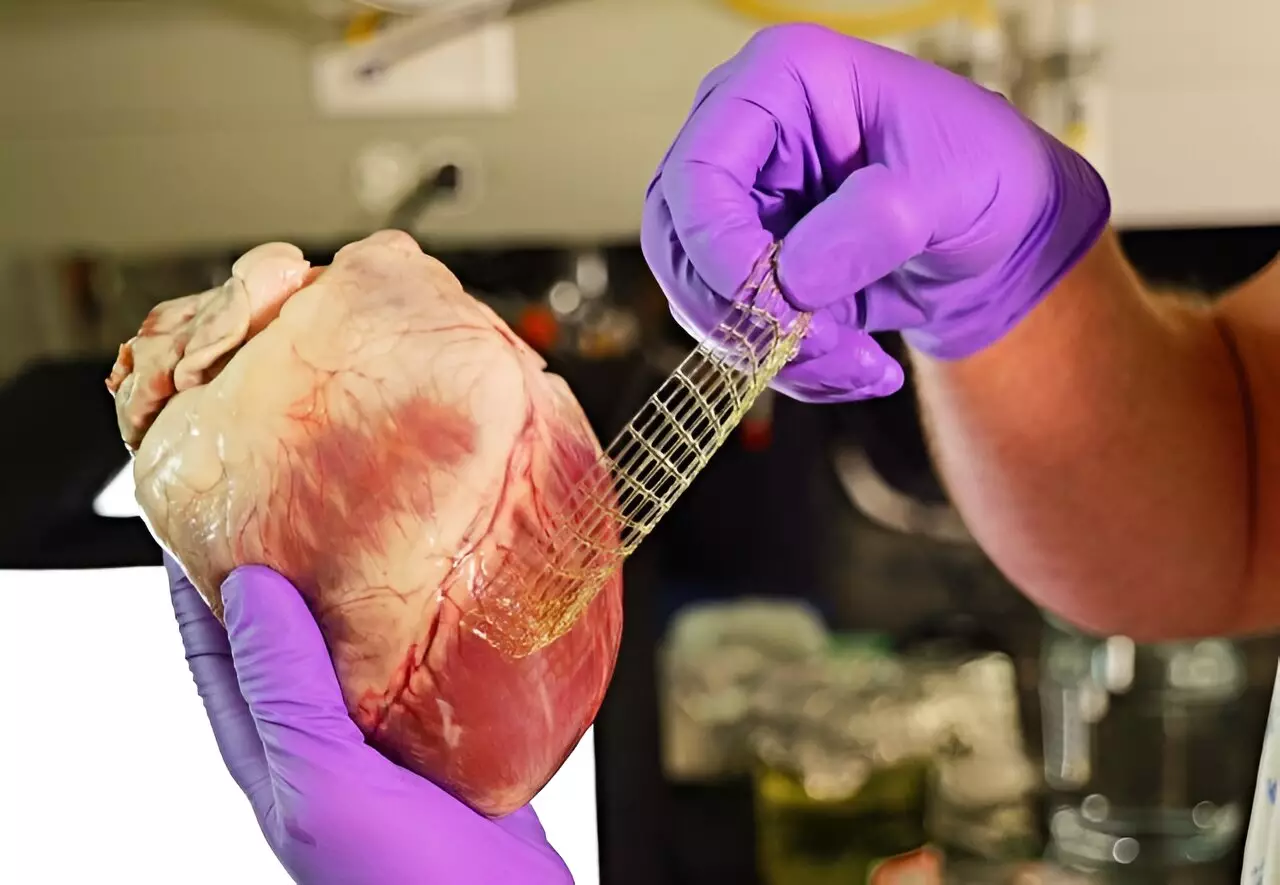

The implications of this development are both exciting and wide-ranging. The fluorescent 3D printed materials created using the CLEAR method hold the potential to yield an array of medical solutions, including drug-delivery systems directly to affected organs, cartilage patches, and even pioneering needle-free suturing techniques that could enhance surgical practices.

Burdick’s team envisions a future where these advanced materials will not only support tissue but also actively participate in repairing and regenerating damaged organs. The promising results from initial laboratory testing indicate that these materials can easily adhere to wet tissues, making them ideal candidates for immediate use in clinical settings. The team is taking tangible steps towards this goal, with plans to conduct more studies focused on how these materials interact with human tissues.

The significance of the CLEAR technique transcends the realm of medicine, offering invaluable prospects for research and manufacturing as well. Its environmentally friendly approach eliminates the need for excessive energy consumption typically required for the curing process of 3D printed materials. This not only enhances the efficiency of production but also has the potential to reduce the ecological footprint associated with manufacturing processes.

Moreover, the versatility of the CLEAR technique makes it suitable for various applications across multiple disciplines, from engineering to consumer products. As detailed insights into the mechanical properties of materials enrich our understanding, it could catalyze significant advancements in numerous fields.

The work done by Burdick and his team embodies a critical leap forward in the confluence of 3D printing and biomedical applications. By developing materials that combine flexibility, toughness, and a method for personalized fabrication, they have opened the door to innovations that may dramatically alter how we approach tissue repair and regeneration. As research continues and studies are conducted, the hope is that these breakthroughs will not only advance medical science but also foster broader shifts in how custom-crafted materials can be utilized across diverse industries. The intersection of technology, biology, and environmental considerations could set a precedent for sustainable practices in 3D printing, signifying a watershed moment for the future of biomaterials.