In recent years, the construction industry has witnessed a significant shift towards incorporating advanced materials that enhance structural integrity, efficiency, and longevity. Among these materials, ultra-high-performance concrete (UHPC) stands out due to its unparalleled strength and durability. However, one of the ongoing challenges in the field of structural engineering is understanding how UHPC behaves when it is confined by fiber-reinforced polymers (FRP). A recent study conducted by a team of researchers from Huazhong University of Science and Technology and Southern University of Science and Technology has introduced a pioneering analysis-oriented stress–strain model that significantly improves our understanding of this complex interaction.

Traditional models have effectively characterized the stress–strain relationships of normal-strength concrete (NSC) confined by FRP. Nevertheless, these models fall short when subjected to the unique behaviors exhibited by UHPC. The study led by S.S. Zhang, J.J. Wang, Guan Lin, and X.F. Nie aims to bridge this critical gap by exploring the failure mechanisms of UHPC under concentric compression and developing a model that accurately reflects these dynamics.

Prior to this study, engineers often relied on the assumption of stress-path independency, which worked well with NSC but proved ineffective for UHPC. The investigators sought to challenge these outdated paradigms and focus on the particular attributes of UHPC. This new approach has the potential to transform how structural engineers measure and predict UHPC performance under various conditions.

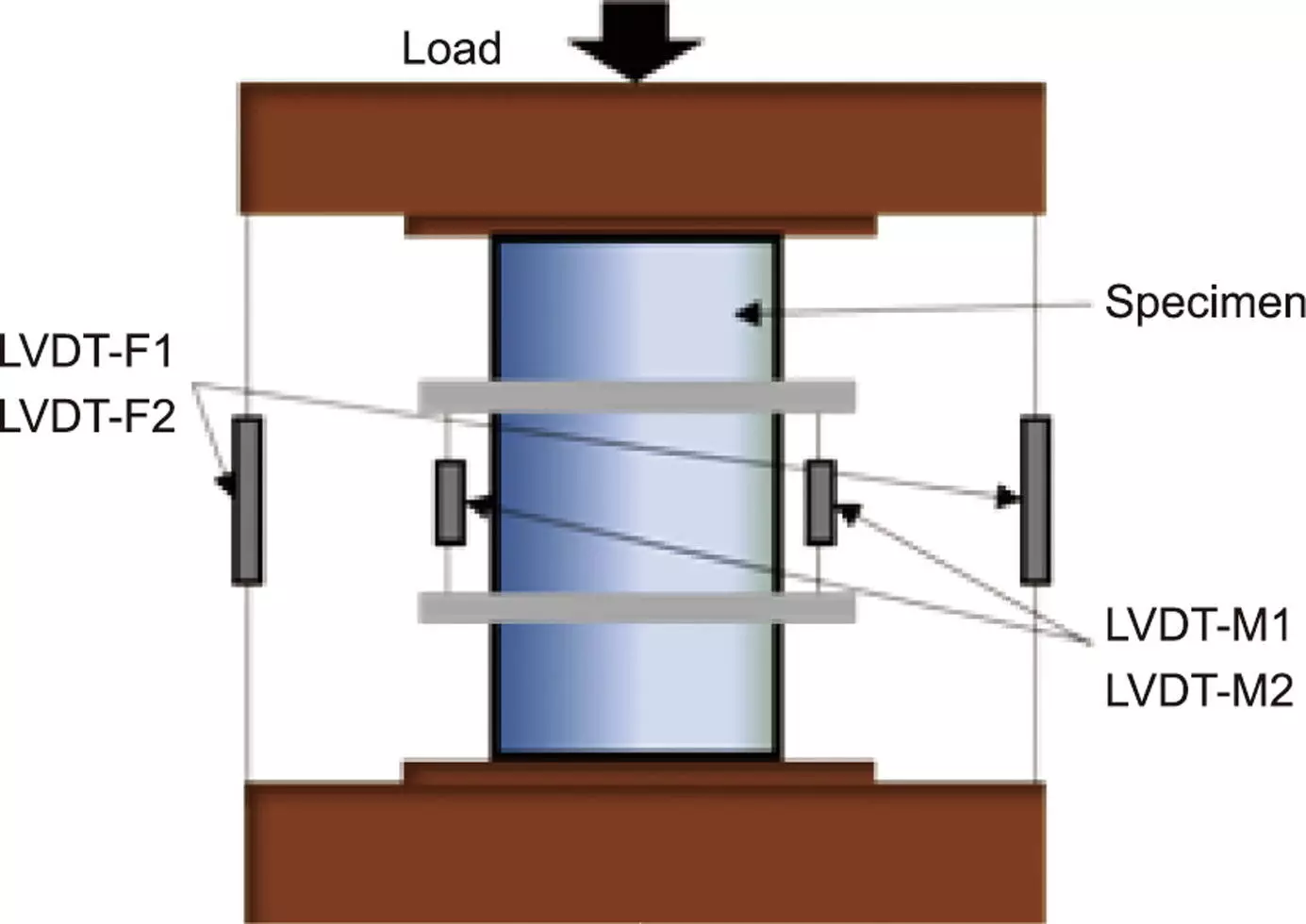

To validate their new model, the research team undertook a comprehensive series of experiments to observe the behavior of UHPC when confined by FRP. Their findings highlighted that the formation of major diagonal cracks results in significant lateral expansion, challenging the effectiveness of earlier models. In traditional models, the assumption of uniform confining pressure is incompatible with the unique responses of UHPC. As a result, the researchers introduced variables to examine how these cracks influence the confining pressure experienced by the UHPC.

The experiments illustrated a critical revelation: the effective confining pressure diminishes due to this non-uniform expansion, invalidating the stress-path independency that had previously been a keystone for modeling NSC. This unprecedented insight prompted the development of a revised model that integrates stress-path dependency into its framework.

The new analysis-oriented model has undergone rigorous testing against a database of empirical findings. Validation of this model confirmed its capacity to predict the stress–strain behavior of FRP-confined UHPC with remarkable accuracy. This success elevates the model as a valuable tool for engineers who require reliable analytics for designing structures that incorporate UHPC.

The innovative approach taken by the researchers to adjust the confining pressure and introduce an equation tailored for the confining pressure gap has proven pivotal. By capturing the nuances of UHPC behavior more accurately than previous models, this new framework empowers engineers to optimize their designs and enhance safety in construction.

The implications of this research extend well beyond academic interest. The newly developed model offers practical applications in designing and analyzing UHPC structures, promoting enhanced performance and longevity. As construction projects increasingly demand innovative materials and increasingly ambitious designs, the ability to accurately predict the behavior of UHPC will lead engineers to create safer and more efficient structures.

Moreover, as the industry gravitates towards sustainability and efficiency, the insights from this research could pave the way for novel applications of UHPC across multiple structural contexts. The research opens up avenues for future studies, encouraging a deeper exploration into the interactions between advanced materials and innovative structural techniques.

The groundbreaking model introduced by S.S. Zhang and his colleagues marks a significant advancement in the field of concrete engineering. By addressing the limitations of existing models and providing a more nuanced understanding of UHPC’s compressive behavior when confined by FRP, this study equips engineers with the knowledge they need to push the boundaries of modern construction. The convergence of innovative material science and engineering principles found within this study will undoubtedly inspire further research, refining high-performance concrete applications to meet the challenges of the future.