In a remarkable stride towards revolutionizing energy production, a dedicated research team led by Dr. Yoonseok Choi from the Korea Institute of Energy Research (KIER) has unveiled a groundbreaking catalyst coating technology. This pioneering development promises to enhance the performance of solid oxide fuel cells (SOFCs) in an astonishingly brief window of just four minutes. This innovation, resulting from collaborations with esteemed professors at leading institutions, has significant implications for the hydrogen economy, positioning fuel cells as formidable players in developing clean energy solutions.

SOFCs have long been recognized for their superior efficiency and versatility, capable of utilizing a range of fuels like hydrogen, biogas, and natural gas. Their ability to facilitate both power generation and combined heat production has catalyzed widespread research into improving their operational efficacy. However, a significant hurdle remains—the sluggish kinetics of the oxygen reduction reaction (ORR) at the air electrode, which ultimately constrains the performance of these fuel cells.

Overcoming the Kinetics Challenge

The crux of the SOFC’s performance lies in how effectively it can facilitate the ORR at the cathode. Unfortunately, the slow reaction rates at this interface have hampered advancements, posing a major challenge for researchers striving to maximize the efficiency of these cells. While efforts have been made to identify new air electrode materials exhibiting high ORR activity, many of these novelties lack chemical stability, which is vital for long-term functionality.

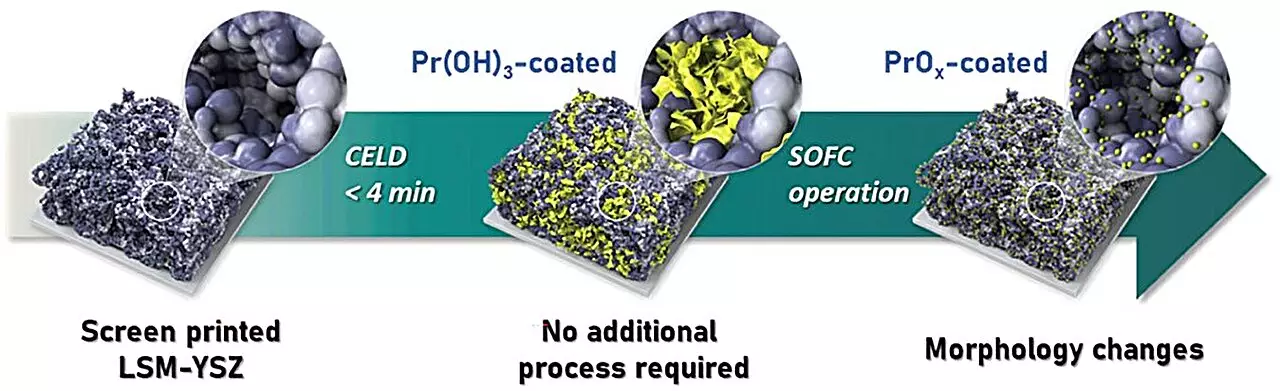

The innovative approach taken by Dr. Choi and his team deviates from the typical path of developing new materials. Instead, they focused on optimizing the well-established LSM-YSZ (lanthanum strontium manganite and yttria-stabilized zirconia) composite electrode. Through meticulous research, they discovered a method to apply a nanoscale coating of praseodymium oxide (PrOx) onto this existing material, effectively boosting its ORR performance without compromising its stability.

The Technique Behind The Four-Minute Process

Central to this advancement is a novel electrochemical deposition technique that operates efficiently at room temperature and atmospheric pressure, eschewing the need for complex machinery. The process involves submerging the composite electrode in a solution rich in praseodymium ions and applying electric current, causing hydroxide ions to react with praseodymium and form a uniform precipitate on the electrode surface.

What sets this method apart is its sheer simplicity and speed. Within a mere four minutes, the precipitate transforms into a stable oxide coating that significantly enhances the surface’s capability for oxygen exchange and ionic conduction. This pioneering technique not only underscores the ease of integration into current manufacturing processes but also highlights its potential economic viability for broader industrial application.

Remarkable Outcomes and Performance Enhancements

The research team’s findings shed light on the profound impact of the praseodymium oxide coating on fuel cell performance metrics. Remarkably, the tests yielded a tenfold reduction in polarization resistance, underscoring the coating’s role in addressing the slow kinetics at the cathode. Furthermore, the fuel cell utilizing the coated electrode achieved a peak power density of 418 mW/cm² at 650 degrees Celsius, a staggering increase from 142 mW/cm² observed in uncoated setups. This achievement represents a landmark breakthrough for SOFCs employing the LSM-YSZ composite, marking the highest performance metrics documented in existing literature.

Dr. Choi aptly encapsulated the significance of this technology by stating that the electrochemical deposition method preserves the integrity of existing SOFC manufacturing processes. By enhancing production simplicity and efficiency, this technique positions the application of oxide nano-catalysts as not only feasible but also economically advantageous for companies looking to optimize their fuel cell technologies.

Ultimately, this innovative catalyst coating technology marks a pivotal moment in the quest for cleaner energy solutions. With its ability to elevate fuel cell performance drastically and its compatibility with existing manufacturing techniques, the implications for the future of SOFCs—and, by extension, the hydrogen economy—are nothing short of tremendous. The dawn of this advancement signifies a turning point where clean energy becomes increasingly viable, expanding our arsenal in the fight against climate change.