The field of material science has always been pivotal in advancing technological frontiers, particularly in areas as sensitive and complex as nuclear fusion. A recent study spearheaded by the Oak Ridge National Laboratory (ORNL) illustrates how artificial intelligence (AI) can dramatically reshape the way new materials are discovered for use in fusion reactors. The research underscores an essential commitment to innovating within one of the most challenging domains of modern science, aiming both for efficiency and enhanced performance in nuclear fusion applications.

Under the leadership of ORNL’s AI Initiative Director, David Womble, this project has undergone significant development, culminating in findings that are now detailed in the journal *Scientific Data*. The study’s primary focus is the identification of alloys suited for shielding components in nuclear fusion reactors, which require materials capable of withstanding extreme temperatures and structural stresses.

Historically, tungsten-based alloys have been the go-to choice for these applications due to their impressive resistance to high temperatures. Nevertheless, they fall short of providing consistent shielding, a crucial factor for the safety and efficacy of fusion reactors. Massimiliano Lupo Pasini, an AI data scientist involved in the study, articulated the necessity of breakthrough materials, stating that the physics of fusion demands “exceptional performance at very high temperatures.” This realization has prompted material scientists to rethink the conventional approaches to alloy formulation, exploring more innovative and potentially disruptive combinations.

One of the most significant hurdles in alloy development is the sheer number of possible metallic combinations. Materials science operates within an almost infinite continuum of potential mixtures and properties, thereby rendering traditional methods of trial and error inefficient and time-consuming. This is where AI steps in as a transformative tool, offering a sophisticated approach to identify and evaluate alloy candidates with speed and precision.

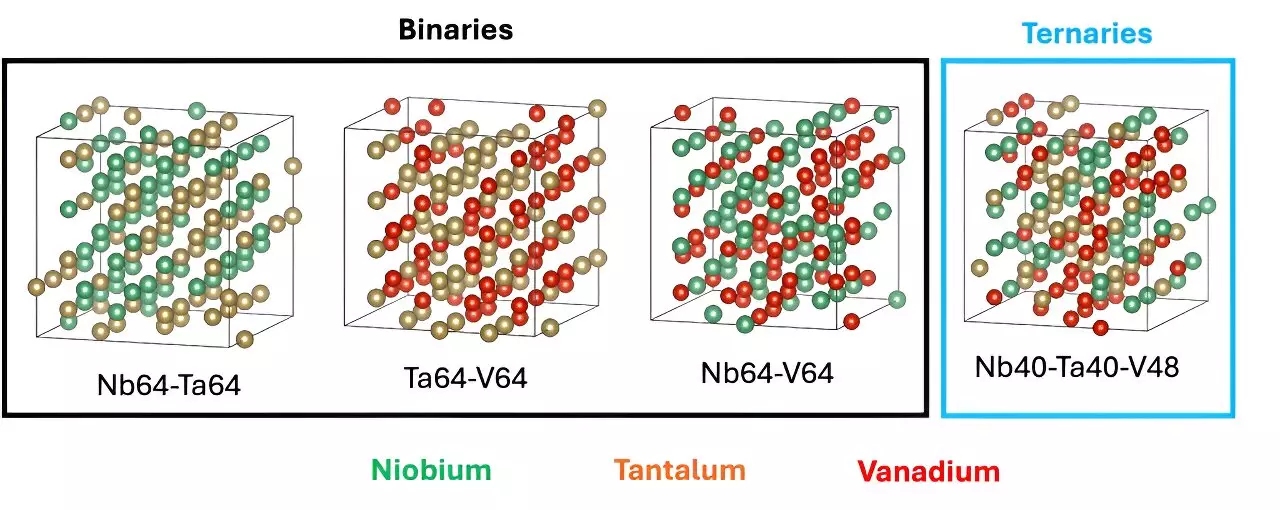

A collaboration of researchers, including prominent figures like German Samolyuk, Jong Youl Choi, Markus Eisenbach, Junqi Yin, and Ying Yang, harnessed AI to sift through a massive landscape of material possibilities. They succeeded in generating a database that has enabled the identification of three critical elements that could serve as potential alloy components. This systematic methodology not only speeds up the discovery process but also shifts the burden of guesswork, maximizing research efficiency.

Lupo Pasini emphasizes that this initial database is just the beginning. To support the design of innovative refractory high-entropy alloys, the team recognizes the need to expand their work to cover effective combinations of six elements. Moreover, they face substantial challenges related to the computational expense of quantum mechanical calculations, which are essential for confirming the theoretical efficacy of these alloys.

The project faced additional hurdles beyond mere data generation. To create a robust AI model, researchers invested considerable time and computational resources using supercomputers like Perlmutter and Summit, which are among the most advanced systems available. Lupo Pasini noted that the data generation process alone spanned over a year, illustrating the depth of effort required to lay the groundwork for future alloy discovery.

Future work will focus on training the AI model to better understand the myriad combinations of the identified elements at various concentrations. By leveraging machine learning, the researchers hope to refine the trial-and-error process traditionally utilized in material discovery. By accelerating the identification of alloy compositions, the team aims to contribute not just to the scientific community but also to the downstream applications of fusion technology, which hold the potential for transformative energy solutions.

As the landscape of nuclear fusion research evolves, the integration of AI in material science is set to redefine traditional boundaries. With their groundbreaking work at ORNL, researchers are paving the way for novel alloy development that could dramatically enhance the safety and efficiency of fusion reactors. As scientists explore the intersection of artificial intelligence and material innovation, the potential for discovery appears limitless, opening new avenues for creating the next generation of fusion technologies. The implications of such advancements could be profound, potentially unlocking a future where clean, sustainable energy sources become a reality rather than a distant ambition.