In a groundbreaking development, researchers at the ARC Center of Excellence for Transformative Meta-Optical Systems (TMOS) have initiated an exciting journey towards creating metasurface-enabled tractor beams. This innovative technology has roots in science fiction, where light rays possess the ability to attract particles, but it is slowly becoming a reality. The significant advancement showcased in the latest research by a University of Melbourne team explores a solenoid beam constructed using an ultra-thin silicon metasurface, an optimization that could transform various fields, from medical procedures to material manipulation.

Breakthroughs in Miniaturization and Efficiency

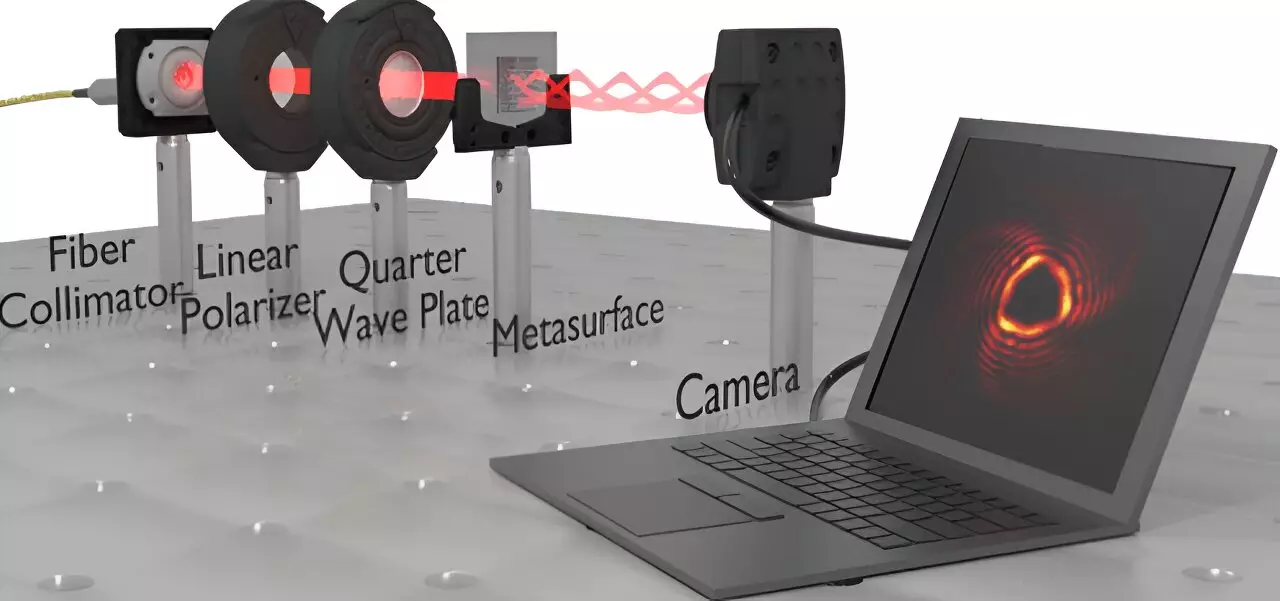

Prior attempts to generate such solenoid beams depended on cumbersome special light modulators (SLMs), which rendered practical applications in handheld devices nearly impossible. However, by shifting to a nanopatterned silicon metasurface that is only about 1/2000 of a millimeter thick, this team has broken down barriers related to size, weight, and energy consumption. As the research indicates, the metamaterial is pivotal in not just simplifying the technology but also enhancing its effectiveness—traits that are quintessential for future applications.

The implications of this innovation reach beyond mere curiosity; the ability to manipulate light in such a precise manner allows for potential breakthroughs in non-invasive medical techniques. Traditional methods of obtaining biopsies involve tools like forceps, which can lead to tissue damage. A metasurface-enabled solenoid beam could provide a safe alternative that minimizes trauma, potentially transforming diagnostic procedures and patient care.

Understanding the Science Behind Solenoid Beams

At the heart of this research lies the understanding of how light can exert forces differently based on its configuration. While conventional light beams typically exert an outward push, solenoid beams possess the unique capability of pulling particles towards the source—akin to the mechanism of a drill collecting wood shavings. In this novel approach, the research team was able to design a beam that is both versatile and high-performing, offering a substantially more flexible set of conditions than previous iterations.

Moreover, utilizing electron beam lithography and reactive ion etching to create the precise phase hologram for the desired beam pattern illustrates the meticulous engineering involved. When subjected to a Gaussian beam input, approximately 76% is effectively transformed into a solenoid beam and separates from the unconverted light. The fact that they were able to characterize this beam from a distance of 21 centimeters also highlights the practical applicability of their findings, suggesting a more user-friendly experience.

A Vision for Future Technologies

Lead researcher Maryam Setareh envisions a world where the compact nature and high efficiency of this technology could lead to novel applications. This perspective is not merely optimistic; it is grounded in tangible progress within the realm of optical engineering. As researchers continue to unveil the properties of solenoid beams, the overarching potential could revolutionize how we address complex challenges in medicine, materials science, and even robotics.

As we stand on the brink of this transformative breakthrough, the marriage of science fiction and scientific reality seems closer than ever, promising new frontiers for exploration in technology that could redefine our interaction with the physical world. In a time when innovation drives society forward, advancements like those at TMOS illuminate the path ahead, leading us into an era of unprecedented optical manipulation.