Fluidic technologies are the backbone of several industries, ranging from healthcare to pharmaceuticals, and even environmental engineering. The need to accurately control the capture and release of chemical and biological fluids is paramount in ensuring precision in various applications. Current systems often struggle with challenges such as contamination, liquid transfer inefficiency, and inadequate disposal mechanisms. Conventional methods often employ disposable plastics, which contribute to a growing environmental crisis. Thus, the development of innovative alternatives that are efficient, sustainable, and reliable is crucial.

Recent research conducted by a team led by Professor Wang Liqiu at The Polytechnic University of Hong Kong (PolyU) introduces a groundbreaking solution to these pressing challenges: the Connected Polyhedral Frames (CPFs). This innovative fluidic processor enables a reversible and programmable method for the precise capture and release of various liquids. Dr. Zhang Yiyuan, the first author of the study published in *Nature Chemical Engineering*, emphasizes the potential of CPFs to liquid handle with unprecedented accuracy, effectively categorizing this platform as a meta-metamaterial.

The CPF design works seamlessly across different fluids and materials, which contrasts sharply with the existing fluid handling technologies that struggle with contamination and low volumetric accuracy. This versatility addresses one of the central shortcomings in the current technologies, where the interaction of fluids with solid media often leads to suboptimal performance.

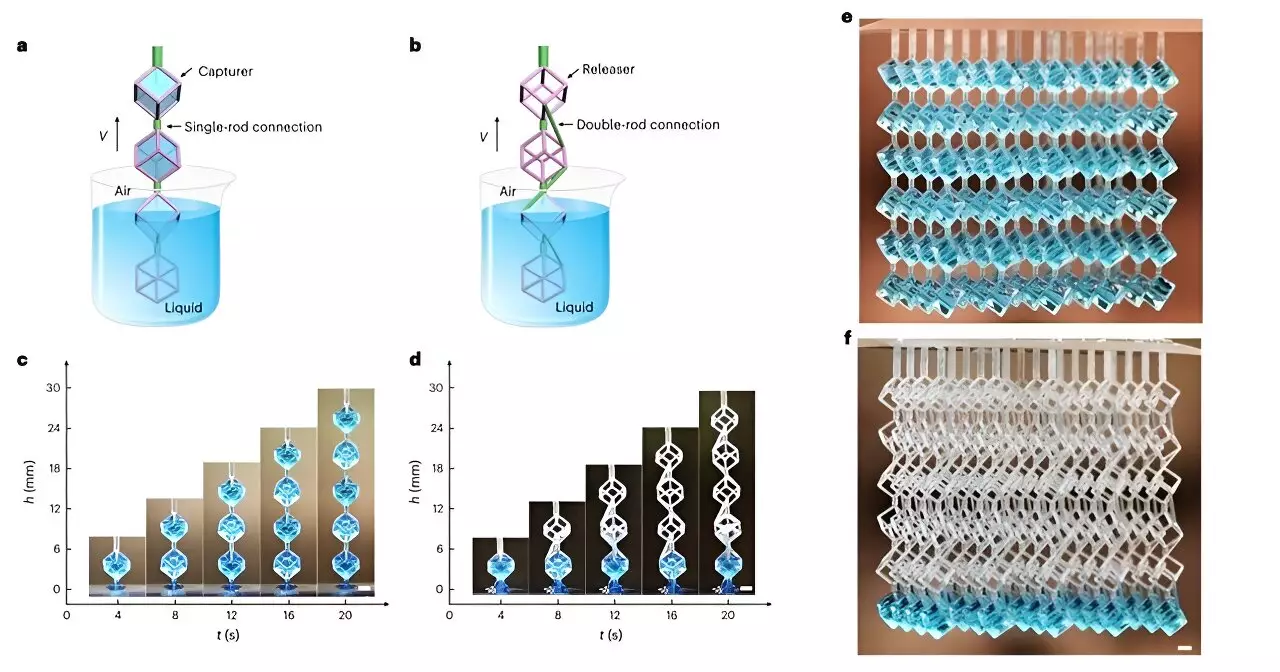

At the heart of CPF technology lies its unique structure. The device features a series of polyhedral frames arranged in a manner that allows fluid capture and release without the typical limitations faced by traditional systems. CPFs utilize different configurations—frames that capture liquids and those that release them—creating a dynamic fluid management system. The innovative aspect of these frames is their capacity to retain or release fluids locally and reversibly by merely managing the liquid continuity between them.

This ability not only simplifies liquid handling but also enhances the volume accuracy and minimizes cross-contamination risks. With CPFs, liquids can be manipulated with high levels of precision, facilitating multi-functional applications in programming patterns and controlling fluid concentrations in three-dimensional spaces.

The implications of the CPF technology extend far into medical fields, as demonstrated through experimental applications. The research team implemented the CPFs in a system for controlled drug release that involved the 3D patterning of essential vitamins. By incorporating these vitamins into hydrogels, they successfully manipulated the release rates through gel thickness, showcasing the system’s versatility in pharmaceutical development.

Moreover, the advantages of CPFs are not limited to drug delivery. In sampling processes, traditional methods have suffered due to residue issues that often compromise the integrity of samples. The CPFs significantly outperform these traditional devices by offering an effective mechanism for fluid release, particularly in delicate processes such as viral detection. The research demonstrated this by achieving results with viral samples where older methodologies failed.

In addition to these medical applications, the engagement of CPFs in microbial development illustrates their compatibility with various biological materials, thereby increasing efficiency and product yield in microbial reactions.

The versatility of CPFs doesn’t stop at academic or medical research. Their potential impact on environmental applications is equally compelling. By creating a commercial-scale humidifier prototype, the research team highlighted the efficiency and sustainability of this technology. The increased water storage capacity and lower water flow requirements of the CPF system present a significant improvement in energy efficiency for humidity control systems. Their structure also facilitates effective gas absorption, which can be instrumental in carbon capture processes.

The research indicates that CPFs may contribute to an ideal CO2 cycle—enhancing both carbon sequestration and reuse—thus addressing a critical component of environmental sustainability.

The Connected Polyhedral Frames represent a significant advancement in fluidic technology, offering solutions to long-standing challenges associated with liquid handling. By enabling precise control over the capture and release of liquids, CPFs not only set a new standard in performance and versatility but also inspire future research and technological breakthroughs across various fields. The innovations stemming from this research may very well transform the way fluids are managed in both scientific and industrial contexts. As we continue to face environmental challenges, such advancements may be key to creating sustainable solutions that align with our global needs.