The world is grappling with a significant environmental dilemma, primarily fueled by the rampant use of plastics and synthetic materials over the past few decades. Since the 1950s, our insatiable demand for convenience has led to the production of around 8.3 billion metric tons of polymers, with only a meager fraction being recycled effectively. This staggering statistic represents not just waste but also a direct threat to ecosystems and human health. With the majority of these materials ending up in landfills or incinerators, the urgency for innovative recycling technologies becomes paramount.

Insights from Groundbreaking Research

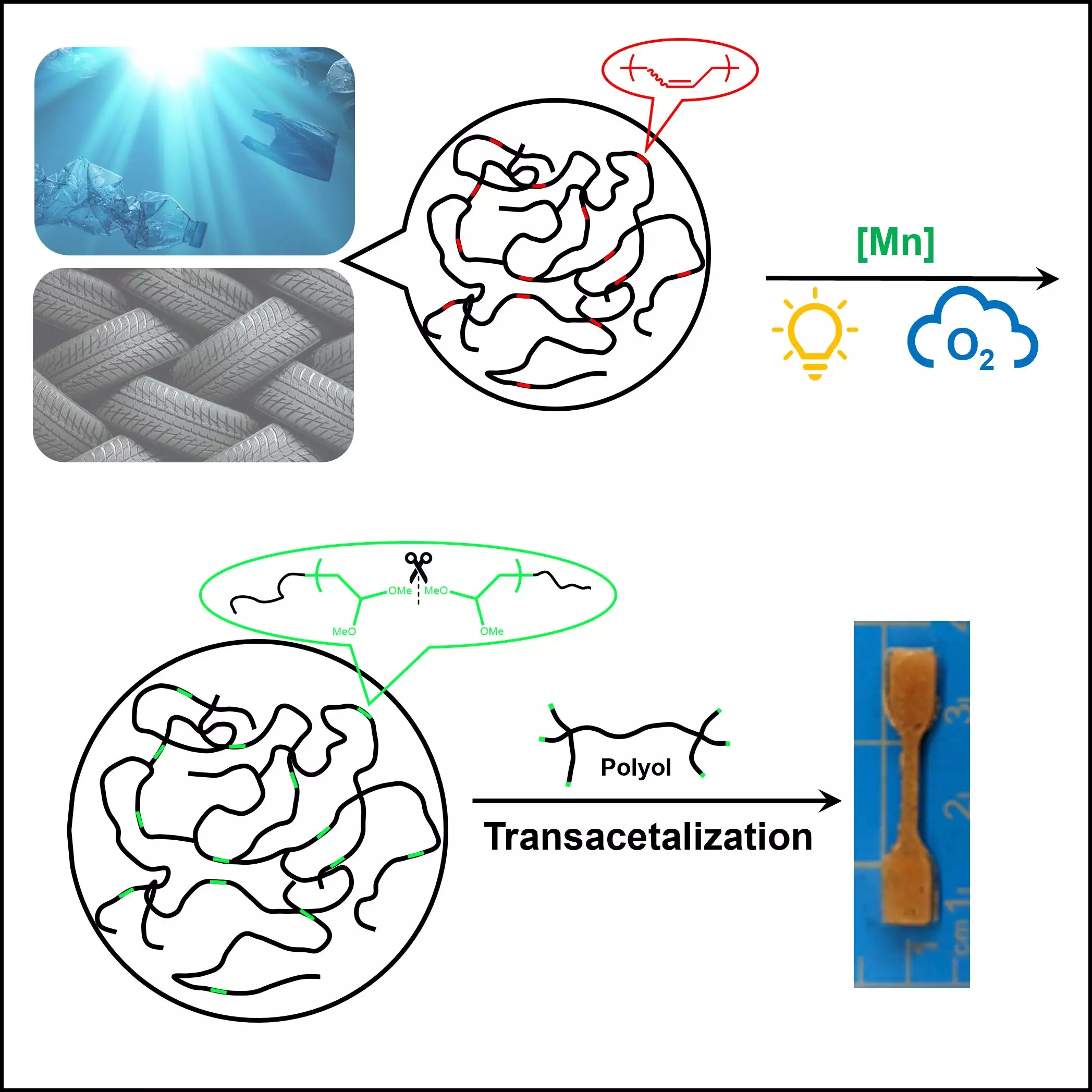

In a pivotal study found in *Cell Reports Physical Science*, Dr. Junpeng Wang and his research team from The University of Akron take significant steps towards addressing these challenges. Their transformative approach leverages the powerful combination of oxygen and light to dismantle unsaturated polymers like rubber and plastics without the baggage of conventional methods. This research is a beacon of hope, as it suggests more efficient ways to recycle materials that have long been considered irreparable due to their stable hydrocarbon structures.

Rethinking Polymer Transformation

Historically, the obstacles surrounding the recycling of polyolefins—the most widely used category of plastic—have largely been rooted in their chemical resistance. Traditional recycling methods relying on ozonolysis and other oxidative processes often fall short due to their impractical energy requirements and the generation of harmful by-products. Dr. Wang’s research introduces a paradigm shift. By focusing on modifying the polymers to include unsaturation, the research team enhances their reactivity, a critical step toward effective recycling.

What stands out in this innovative approach is not only its reliance on abundant and environmentally benign oxygen as the primary oxidant but also its ability to operate efficiently under normal conditions. The catalyst activated by light can achieve polymer breakdown at room temperature, representing a game-changer in the sector of polymer science.

Scalable Solutions for a Global Issue

One of the most thrilling aspects of this research is its potential for scalability. Conventional recycling processes are often energy-intensive, featuring significant hurdles that make wide-scale adoption impractical. Dr. Wang and his team’s novel technique, in contrast, presents a solution that is not only efficient but also accessible. With the possibility to harness everyday resources—light and oxygen—this method holds the promise for widespread applicability, ideally suited to meet the global recycling needs in an eco-friendly manner.

Furthermore, the implications of controlled polymer degradation extend far beyond just recycling; they challenge the conventional narrative of waste management and inspire a shift toward more sustainable industrial practices. The intersection of polymer science and environmental stewardship could very well dictate the future of material usage and waste sorting systems.

Looking Ahead: The Future of Recycling Innovation

The strides made by Dr. Wang and his team not only contribute to a better understanding of polymer degradation but illuminate the path toward innovative and practical solutions to one of the pressing environmental challenges of our time. As we stand on the precipice of a new era in materials science, the need for collaboration and research investment in green technologies has never been more critical. The findings signal a beacon for future research directions, advocating for the urgent adoption of sustainable practices that could redefine the lifecycle of plastics and polymers altogether.