Recent advancements in 3D printing technology by engineers at the University of California San Diego promise to reshape materials manufacturing towards a more sustainable future. The novel method, highlighted in a publication in Nature Communications, employs an environmentally friendly approach utilizing a polymer ink combined with a saline solution to fabricate solid structures. This innovative combination not only simplifies the printing process but also mitigates the environmental impact typically associated with traditional manufacturing techniques.

At the core of this breakthrough is a polymer solution called poly(N-isopropylacrylamide) or PNIPAM. When this polymer ink is introduced into a calcium chloride salt solution, it undergoes an instantaneous solidification process upon interaction with the salt water. This reaction is driven by the salting-out effect: salt ions have a strong attraction to water, thereby extracting water molecules from the polymer solution. As water is drawn out, the hydrophobic chains of the PNIPAM aggregate, resulting in immediate solid formation. Importantly, this entire process occurs under ordinary ambient conditions without the requirement for specialized tools, toxic substances, or high energy usage.

One of the most striking advantages of this new method is its reversible nature. The solid structures produced can be easily dissolved in fresh water, reverting back to their liquid form, which allows for the PNIPAM ink to be reused multiple times. This feature provides an innovative solution for recycling polymer materials, addressing significant concerns about plastic waste and environmental degradation caused by traditional manufacturing processes. Jinhye Bae, a senior author of the study, emphasizes the importance of this eco-friendly approach, saying, “This offers a simple and environmentally friendly approach to recycling polymer materials.”

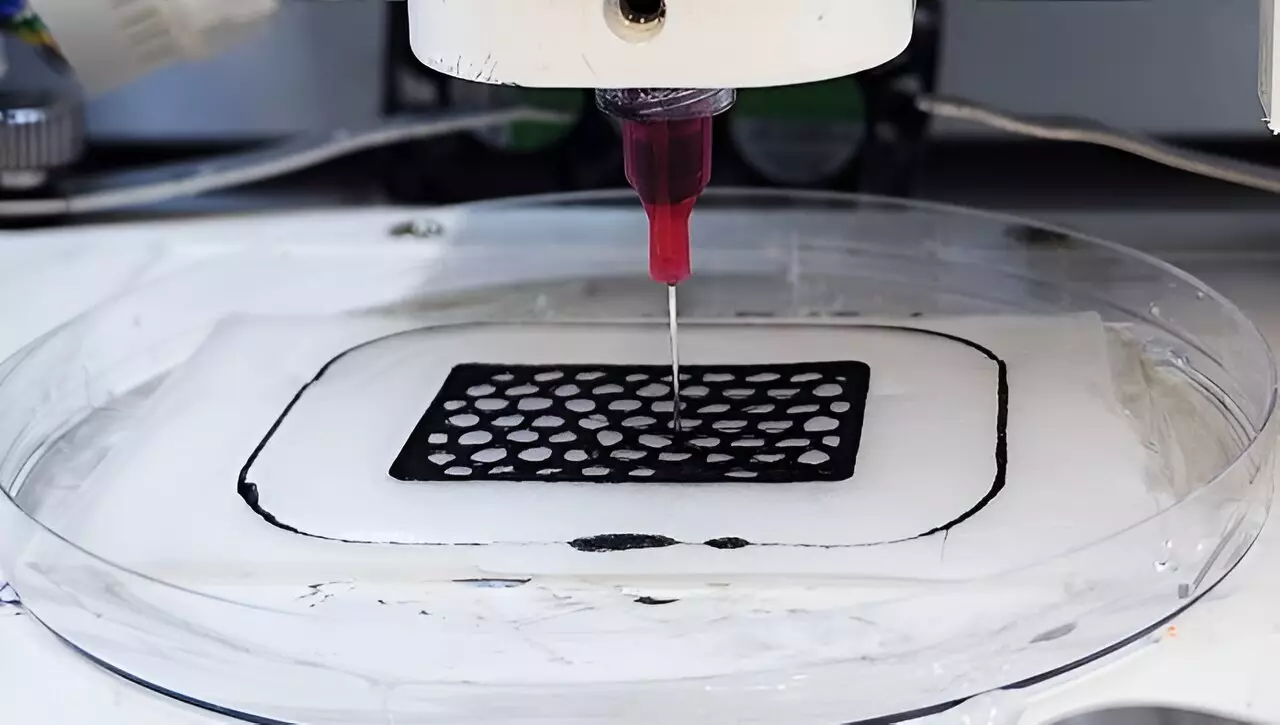

Not only does this novel technique enable the creation of basic solid structures, but it also demonstrates versatility through the ability to incorporate additional materials into the printing process. For instance, researchers successfully printed functional electronic circuits by combining PNIPAM with carbon nanotubes. This pioneering advance allowed for the development of a circuit capable of powering a light bulb, while still maintaining the remarkable property of being water-soluble. Such potential opens up new avenues for creating recyclable electronic components.

The implications of this new printing technique reach far beyond simple manufacturing improvements. By harnessing the interactions between a polymer and a saline solution, Bae and her team envision prospects for a sustainable polymer manufacturing industry. The capacity to produce biodegradable, recyclable materials at room temperature without hazardous conditions can revolutionize how industries approach material creation and waste management. Overall, this groundbreaking work illustrates a significant leap towards marrying technological advancements with environmental consciousness, heralding a new era of forward-thinking manufacturing practices.