As society transitions from fossil fuels to sustainable energy solutions, the emphasis on electric vehicles (EVs) intensifies. However, the effectiveness of this shift heavily depends on advancements in battery technology—specifically, the need for high-performance batteries that support long-range travel without frequent recharging. A transformative approach to energy storage is emerging with the development of structural batteries, which promise to not only store energy but also replace conventional structural components in vehicles and other devices.

Structural Batteries: A Dual Purpose Innovation

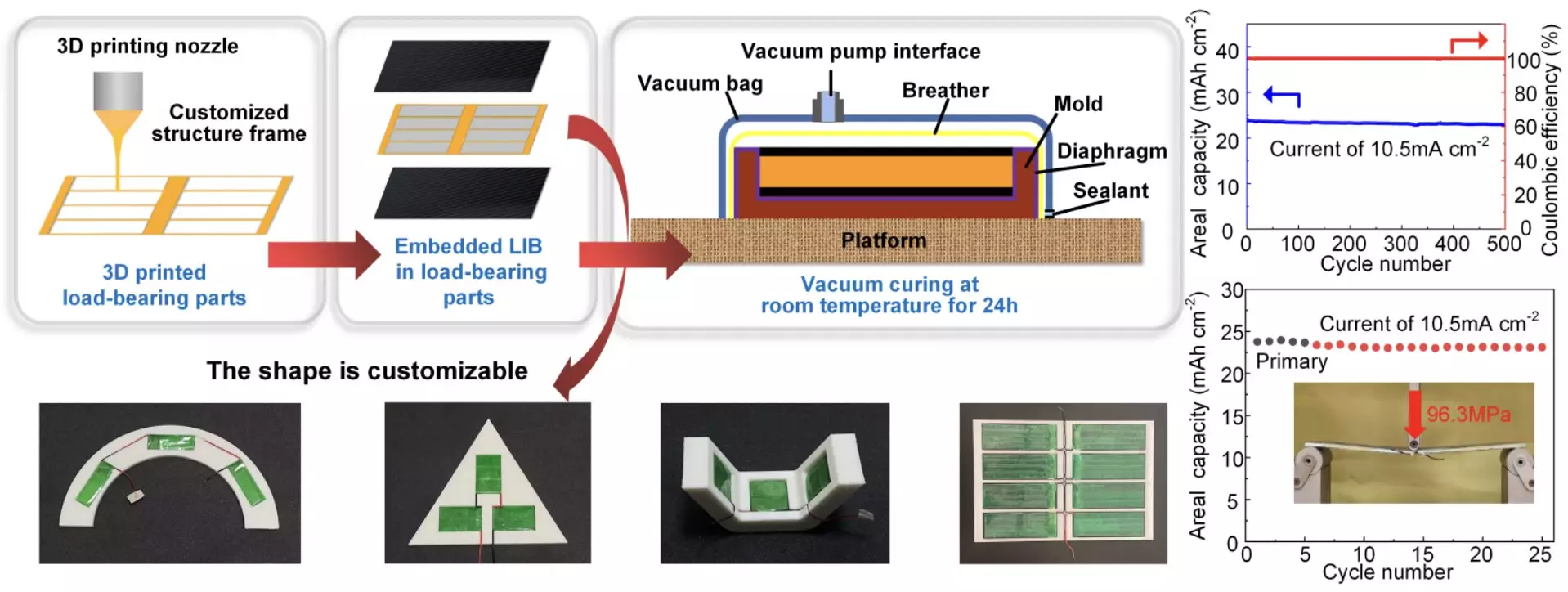

Structural batteries offer a groundbreaking approach by integrating energy storage capabilities directly into the vehicle’s structure. This innovation contrasts sharply with traditional batteries, typically seen as detached units requiring designated space and mounting. By embedding energy cells into the very fabric of a vehicle’s components, structural batteries conserve space and reduce overall weight, two crucial factors in enhancing the efficiency and performance of electric vehicles. Researchers from Shanghai University have taken significant strides in this area, showcasing a methodology for creating high-performing structural batteries tailored for specific geometries.

The research team’s findings are particularly compelling, as they indicate that this dual-purpose solution can greatly enhance energy density while maintaining high load-bearing capacity. “This study aims to design an integrated energy storage and load-bearing structure,” asserts Yinhua Bao, the lead author. The implications are substantial—not only could electric vehicles benefit, but indeed any applications requiring lightweight yet robust energy storage solutions could find this technology revolutionary.

A critical aspect of this innovation lies in the application of 3D printing technology. The researchers have effectively employed this technology to create customizable geometrical configurations for structural batteries. Unlike conventional manufacturing processes that may be restrictive in design, 3D printing allows for rapid prototyping and the ability to tailor structures based on specific requirements. With this, the promise of high-energy density and mechanical stability becomes more attainable, particularly crucial in high-stress environments such as vehicular applications.

The significance of design elements cannot be understated. According to Bao, the utilization of a decoupled structure enables better mechanical performance by mitigating the deformation of energy storage units under load. Consequently, this focuses stress on the structural framework, preserving the integrity and functionality of the energy cells. The research not only highlights the benefits of 3D printing but also underscores the critical role of material science in achieving high-performance batteries.

In testing their prototype, the researchers reported impressive outcomes, including a high energy density of 120 Wh/kg and maintaining around 92% of its capacity after 500 operational cycles. Most notably, the battery showed remarkable resilience under mechanical stress, retaining almost all capacity when subjected to significant tension and bending. This robustness is crucial, especially in automotive contexts where energy storage elements must endure various physical forces without compromise.

By employing advanced simulation techniques such as finite element analysis, the researchers could optimize battery design proactively. This anticipatory approach to structural integrity not only presumes durability but also adds to the overall safety of future electric vehicle systems. It reflects a shift from reactive strategies in engineering to forward-thinking design philosophies, which are necessary for developing reliable energy storage solutions.

While electric vehicles stand to gain considerably from this technology, the applications for structural batteries extend far beyond the automotive sector. Autonomous robots and logistics vehicles could employ such batteries, maximizing efficiency and functionality without sacrificing space or performance. The adaptability of structural battery technology allows it to fit a variety of industrial and consumer needs.

Future explorations into unmanned aerial vehicles (UAVs) and robotics could yield even further advancements. The potential to scale the manufacturing process through 3D printing sets the stage for widespread adoption, suggesting that these structural batteries could become common in various sectors within a short timeframe.

The research by the team at Shanghai University signifies a crucial step forward in battery technology, marrying the concepts of energy storage and structural integrity. As they continue their investigation into new applications and refine their 3D printing processes, the prospect of a future dominated by highly efficient, multi-functional structural batteries appears increasingly realistic. By breaking down barriers in material performance and manufacturing techniques, we stand on the cusp of a new era in energy storage—one that could redefine mobility and technology as we know it.