In the arena of renewable energy, where efficiency and sustainability are paramount, recent advancements presented by a research team led by Prof. Chen Changlun from the Hefei Institutes of Physical Science have emerged as a beacon of hope. Their groundbreaking work on cobalt-doped nickel hydroxide bipolar electrodes and non-noble metal catalysts has redefined the landscape of hydrogen production through improved two-step water electrolysis. This innovation not only enhances efficiency but also addresses the industry’s pressing challenges related to energy integration and safety.

Traditional alkaline electrolyzers have long struggled with the inherent discrepancies in output when paired with fluctuating energy sources, such as solar and wind. Problems such as the mixing of hydrogen and oxygen gases under high-pressure conditions hinder operational capabilities and introduce safety risks. This is where two-step water electrolysis shines, promoting the separated production of hydrogen and oxygen, thus eliminating the necessity for costly membrane separators that add to the complexity and expense of the systems.

From Limitations to Innovations: The Role of Cobalt Doping

Historically, nickel hydroxide electrodes have been plagued by performance limitations, particularly regarding their electric buffering capacity and stability under charge and discharge conditions. However, the approach taken by Prof. Chen’s team, involving a one-step electrodeposition method to create cobalt-doped flexible nickel hydroxide bipolar electrodes, presents a significant leap forward. The incorporation of cobalt not only enhances conductivity but also mitigates the unwarranted production of oxygen during hydrogen generation, which is critically needed for optimizing efficiency.

The introduction of non-noble metal catalysts like molybdenum-doped nickel-cobalt phosphide further amplifies the practicality of this technology. Their ability to generate oxygen and hydrogen at designated intervals allows for streamlined energy usage and contributes to lower cell voltages. This strategic separation enhances decoupling efficiency, presenting a more sustainable method of energy conversion that aligns with global advancement standards.

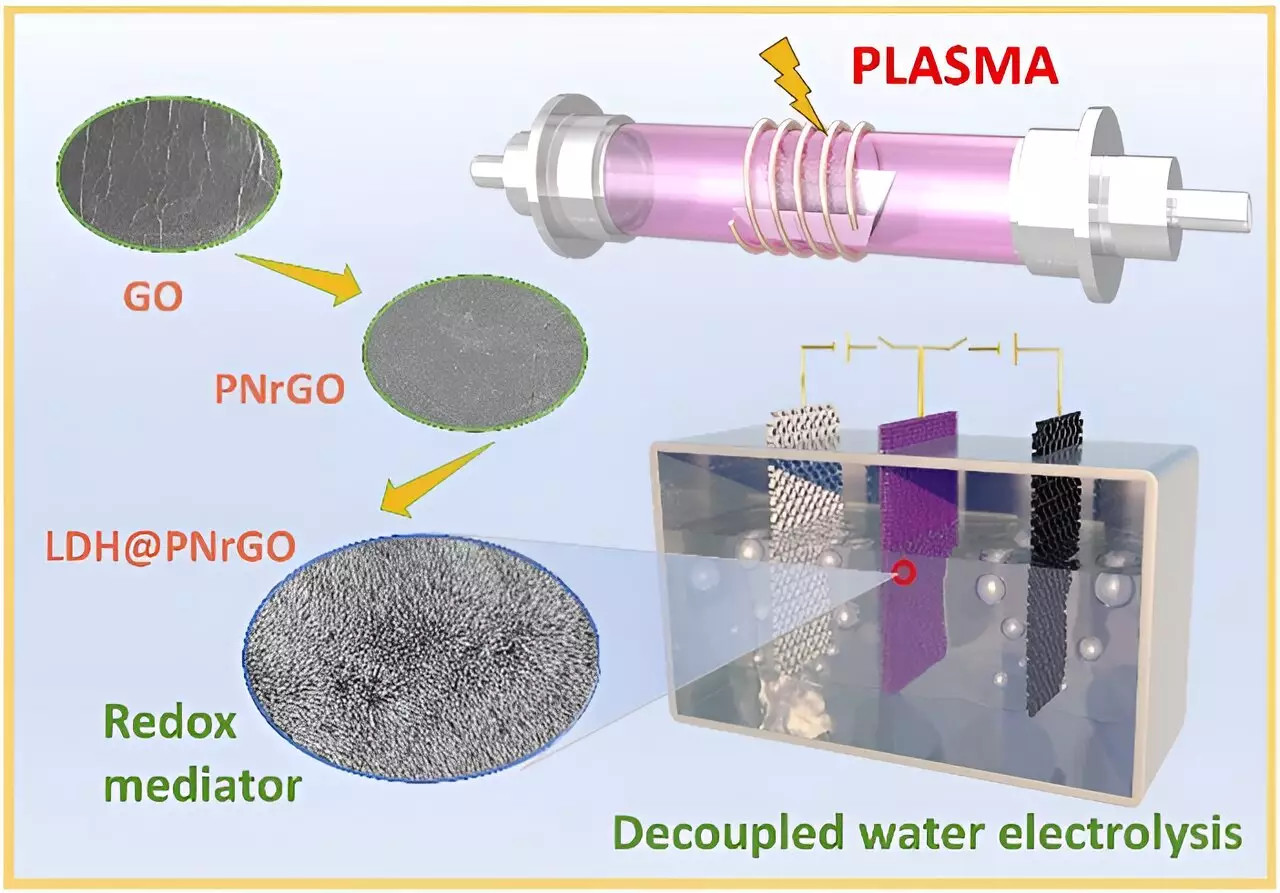

Engineering Enhanced Performance through Plasma Technology

Moreover, the team’s exploration of non-thermal plasma technology to fabricate nitrogen-doped nickel-cobalt layered double hydroxides signals a major breakthrough. Such materials traditionally faced drawbacks concerning capacity and stability, yet, with this innovative technique, the resultant electrodes demonstrate markedly improved conductivity and energy storage capabilities. This is crucial for large-scale applications, such as powering 5G base stations and data centers, where reliability and energy efficiency are non-negotiable.

Furthermore, the adaptability of the developed materials allows for flexibility in energy application settings. By enabling the dynamic production of hydrogen and oxygen in distinct zones and times, the researchers have opened doors for broader uses in a world increasingly reliant on green energy solutions. This initiative marks a pivotal moment not only for the scientific community but also for industries looking to transition to sustainable practices efficiently.

Prof. Chen’s assertion that their performance indicators align with leading global benchmarks underscores the significance of these findings. It represents a promising trajectory towards an operationally feasible hydrogen economy, crucial for addressing climate change and energy crises. The journey toward sustainable and scalable hydrogen production has been invigorated, ensuring that we are one step closer to realizing a cleaner, more efficient future.