Biological systems exhibit remarkable ingenuity, particularly in their design of materials that deliver both strength and flexibility. One compelling example is the sea sponge, which develops layered architectures that harmoniously blend mineral-rich and softer regions. This intrinsic capability not only underscores a natural aesthetic but also embodies profound engineering principles that can be leveraged for innovative synthetic materials.

Nature’s Design: A Template for Innovation

Researchers like Nancy Sottos from the Beckman Institute for Advanced Science and Technology highlight how nature masterfully transforms seemingly fragile materials into rugged constructs through elaborate patterning techniques. “Nature has a way of turning brittle materials into tough ones through intricate patterning,” she states, emphasizing a powerful discovery in material science: the coexistence of stiff and flexible regions within a single structure. This amalgamation allows engineered materials to endure significant strain without compromising their integrity, fundamentally redefining material performance standards.

Frontal Polymerization: A Breakthrough in Material Engineering

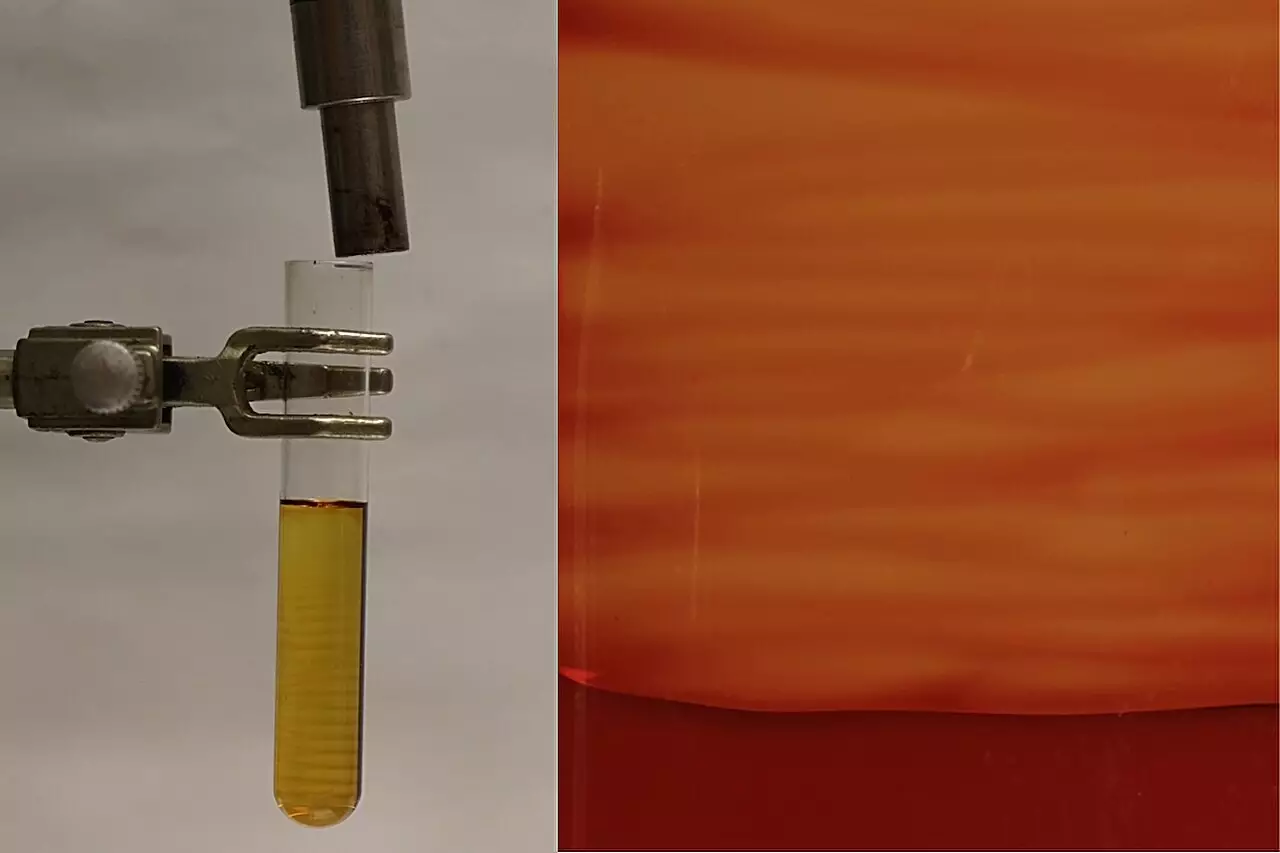

In a pioneering study featured in Nature, Sottos and her colleagues showcased an innovative approach to mimic nature’s efficiency through frontal polymerization. This revolutionary manufacturing technique utilizes heat to incite chemical reactions that yield polymers, bridging the gaps between natural systems and synthetic materials. By building upon previous findings from 2021, the team has refined this technique to facilitate the intentional creation of crystalline structures within the polymers, significantly boosting their toughness and durability.

Jeff Moore, a contributing researcher and a professor of chemistry, articulates the essence of their findings. He notes that while nature relies on organic, spontaneous patterns, past synthetic fabrication has depended heavily on controlled environments and methods. Their breakthrough involves the development of structured materials free from traditional molds and milling processes, heralding a new chapter in material architecture.

The research team employed a morphogenic manufacturing technique that allows for slight chemical modifications to evoke tailored crystalline patterns. This innovative approach was no small feat; identifying optimal reaction conditions demanded weeks of meticulous effort. Justine Paul, the lead author of the study, expressed her satisfaction upon observing the significant morphological transformations that arose from reactions that were intentionally manipulated.

This work resulted in a polymer manifesting both amorphous and crystalline properties, offering a juxtaposition between flexible and rigid components that significantly enhances resilience in end products. The collaborative spirit fostered at the Beckman Institute was paramount in making such advancements possible. Specialists across various disciplines came together, leveraging their unique skill sets to uncover fundamental insights into the architecture of polymers.

The Role of Interdisciplinary Collaboration

Cecilia Leal, a materials science professor, utilized X-ray scattering techniques to provide clarity on how polymer chains interact with each other within the patterned matrices. This exploration is vital, as unraveling the relationships between structure and property is intrinsic to advancing material science. Aerospace engineering professor Philippe Geubelle contributed by simulating the manufacturing process, focusing on understanding the complicated thermo-chemical instabilities that give rise to these heterogeneous materials.

Geubelle emphasized that the success of their endeavor was deeply rooted in the close collaboration among experimentalists and theoretical modelers. The fusion of insights from diverse fields—mechanics, chemistry, and materials science—was instrumental in advancing their project. As Moore aptly pointed out, this achievement underscores the significance of an interdisciplinary environment in harnessing creativity and innovation in tackling complex scientific challenges.

The developments by Sottos, Moore, Leal, and Geubelle signal not only a technical achievement but also an invitation for future innovation in material design. By adopting nature-inspired methodologies, researchers can further explore sustainable and efficient materials for applications ranging from aerospace engineering to everyday consumer products. The interdisciplinary collaborations nurtured at institutions like the Beckman Institute stand as a testament to the power of collective intellectual endeavor, paving the way for the next generation of resilient and multifunctional materials.

The confluence of biology and material science opens doors to a myriad of possibilities, encouraging a shift in how materials are conceptualized and engineered for diverse applications in an increasingly complex world.