In the quest for advancements in lithium-ion battery technology, NCM811 (Nickel-Cobalt-Manganese) materials often emerge as frontrunners due to their high energy density. Nonetheless, the journey towards optimizing their performance is fraught with challenges. The significant issue at hand is the susceptibility of polycrystalline NCM materials to cracking under mechanical stress. Such stresses not only contribute to the deterioration of active materials but also significantly hinder the longevity of the battery lifecycle. It is crucial, therefore, to delve into the chemo-mechanical dynamics of these materials, fostering a deeper comprehension that can lead to improved battery performance.

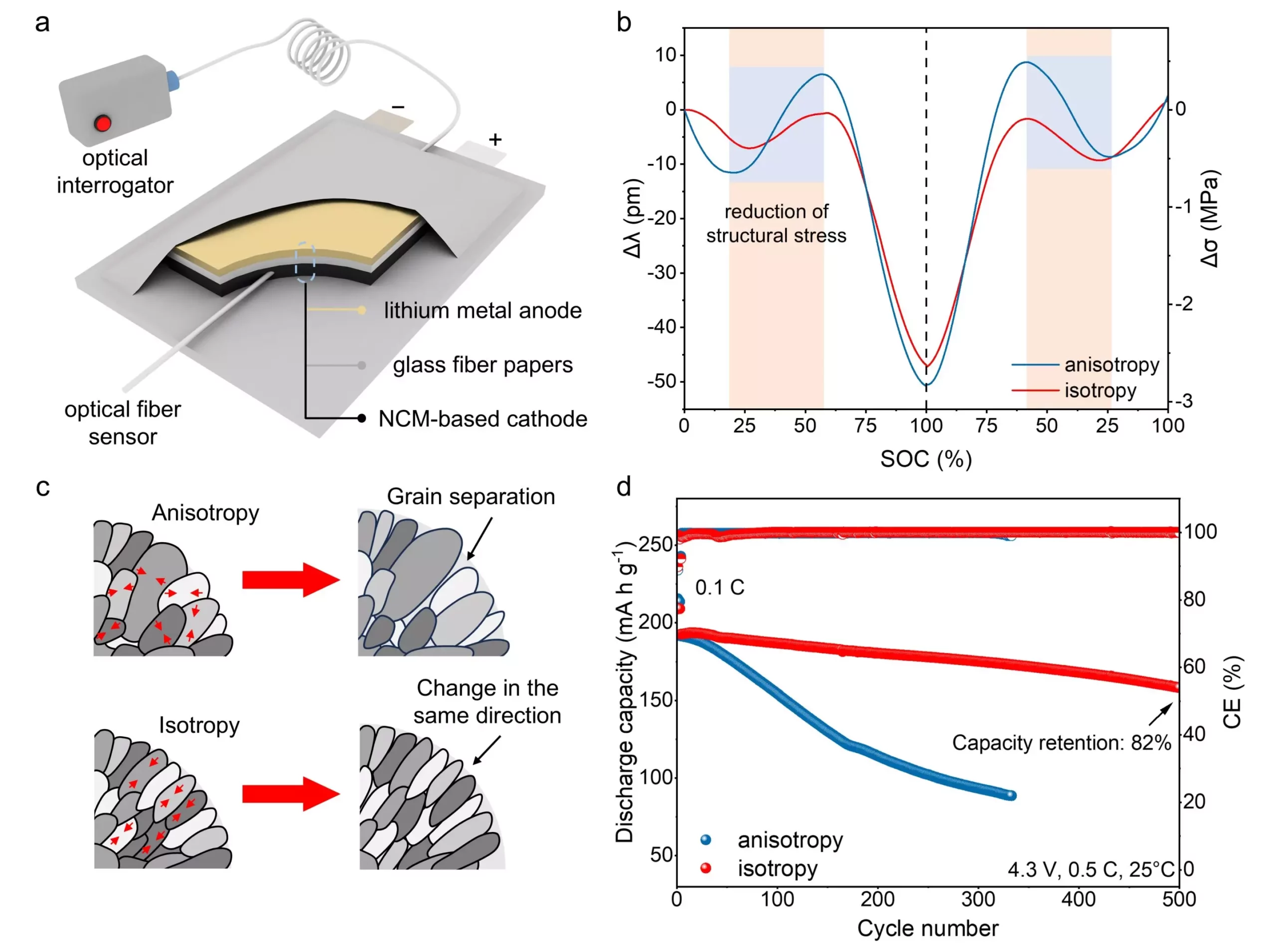

A recent study led by esteemed researchers, Prof. Yunhui Huang and Prof. Zhen Li, sheds light on this issue by leveraging innovative optical fiber technology for real-time stress detection in NCM811 cathodes. The researchers have brilliantly integrated optical fibers into the battery structure, allowing for in situ monitoring of stress changes at the material level. This approach not only enhances our understanding of the stress mechanics involved but also ensures minimal interference with the battery’s overall performance due to the inherent stability and small scale of the fibers.

The findings reveal a duality in stress manifested within the polycrystalline NCM811: chemical stress and structural stress. Chemical stress arises predominantly from the repetitive (de)lithiation cycles—a natural aspect of battery operation. However, the structural stress is particularly concerning, as it is recognized as a catalyst for the development of cracks, ultimately jeopardizing battery functionality. Thus, addressing these cracks is essential for enhancing the operational capacity and efficiency of the battery.

The researchers also identified a correlation between structural stress and the structural changes within the crystalline arrangement during (de)lithiation. They uncovered that variations in the c-axis of the crystal structure, coupled with the anisotropic nature of primary particles in polycrystalline materials, contribute heavily to structural stress. This realization paves the way for potential remedies, such as the development of materials with improved anisotropic properties. By promoting a more ordered arrangement of primary particles, the researchers posited that the stability of chemo-mechanical properties could indeed be enhanced.

The study underscores the potential of employing ordered arrangement structures, which not only alleviate structural stress but also yield impressive performance metrics, such as an 82% capacity retention over 500 cycles at a rate of 0.5C. Prof. Huang emphasizes the transformative role of optical fiber sensing in battery monitoring: “This technology decodes the chemo-mechanical evolution, guiding us towards constructing more robust materials.” As the field continues to innovate, integrating such sensing technologies could be pivotal in ushering in an era of safer, more efficient, and smarter batteries. The intersection of advanced materials science and innovative sensing technologies holds immense promise for the future of energy storage solutions.